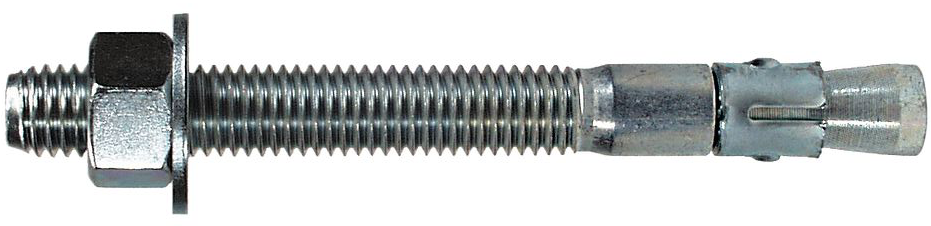

The Wedge-All wedge-style expansion anchor is intended for use in solid concrete or grout-filled masonry. This anchor is best suited in installations where a building code approval for seismic and cracked/uncracked concrete is not required. Threaded studs are set by tightening the nut to the specified torque.

Code listed for cracked and uncracked concrete, and masonry applications, the Strong-Bolt 2 wedge-type expansion anchor is an optimal choice for high-performance even in seismic and high-wind conditions. Dual undercutting embossments on each clip segment enable secondary expansion should a crack form and intersect the anchor location; this feature significantly increases the ability of Strong-Bolt 2 to carry load if the hole expands.

A high-strength screw anchor for use in cracked and uncracked concrete, as well as uncracked masonry. The Titen HD offers low installation torque and outstanding performance. The Titen HD screw anchor is designed for a wide variety of applications such as sill plates, ledgers, post bases, seating, and other holdown applications. The screw anchor is easy to remove when used in temporary applications such as bracing and formwork, or when a fixture needs to be relocated.

The stainless-steel Titen HD is the optimal choice for applications in corrosive or extreme environments such as salt water, or when chemical or corrosive solutions are present. See Stainless-Steel Titen HD for more information.