ASTM F436 sets the standards for Type 1 and Type 3 flat washers, critical components in structural applications. Type 1 washers, crafted from medium carbon steel, and Type 3 washers, made from weathering steel, are indispensable for ensuring the stability of bolted joints in construction projects. With robust mechanical properties such as high hardness and tensile strength, Type 1 washers provide reliable load distribution and resistance to deformation. Meanwhile, the corrosion-resistant nature of Type 3 washers makes them well-suited for outdoor and exposed environments. As pivotal elements in structural assemblies, ASTM F436 washers contribute significantly to fortifying the integrity and longevity of diverse constructions, ranging from buildings to bridges.

*For Weather resistance, see Type 3 products

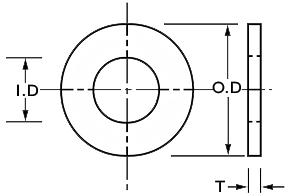

| ASTM F436 Flat Washer Dimensionals | ||||||

|---|---|---|---|---|---|---|

| Nominal WasherD Size Inch | Inside Diam. (ID) | Outside Diam. (OD) | Thickness (T) | |||

| min | max | min | max | min | max | |

| 1/4 | 0.281 | 0.313 | 0.593 | 0.657 | 0.051 | 0.080 |

| 5/16 | 0.344 | 0.376 | 0.656 | 0.720 | 0.051 | 0.080 |

| 3/8 | 0.406 | 0.438 | 0.781 | 0.845 | 0.051 | 0.080 |

| 7/16 | 0.469 | 0.501 | 0.890 | 0.954 | 0.051 | 0.080 |

| 1/2 | 0.531 | 0.563 | 1.031 | 1.095 | 0.097 | 0.177 |

| 9/16 | 0.625 | 0.657 | 1.156 | 1.220 | 0.110 | 0.177 |

| 5/8 | 0.688 | 0.720 | 1.281 | 1.345 | 0.122 | 0.177 |

| 3/4 | 0.813 | 0.845 | 1.436 | 1.500 | 0.122 | 0.177 |

| 7/8 | 0.938 | 0.970 | 1.718 | 1.782 | 0.136 | 0.177 |

| 1 | 1.063 | 1.126 | 1.937 | 2.063 | 0.136 | 0.177 |

| 1 1/8 | 1.188 | 1.251 | 2.187 | 2.313 | 0.136 | 0.177 |

| 1 1/4 | 1.375 | 1.438 | 2.437 | 2.563 | 0.136 | 0.177 |

| 1 3/8 | 1.500 | 1.563 | 2.687 | 2.813 | 0.136 | 0.177 |

| 1 1/2 | 1.625 | 1.688 | 2.937 | 3.063 | 0.014 | 0.177 |

| 1 3/4 | 1.875 | 1.938 | 3.312 | 3.438 | 0.178B | 0.28B |

| 2 | 2.125 | 2.188 | 3.687 | 3.813 | 0.178B | 0.28B |

| 2 1/4 | 2.375 | 2.438 | 3.937 | 4.063 | 0.24C | 0.34C |

| 2 1/2 | 2.625 | 2.688 | 4.437 | 4.563 | 0.24C | 0.34C |

| 2 3/4 | 2.875 | 2.938 | 4.937 | 5.063 | 0.24C | 0.34C |

| 3 | 3.125 | 3.188 | 5.437 | 5.563 | 0.24C | 0.34C |

| 3 1/4 | 3.375 | 3.500 | 5.875 | 6.125 | 0.24C | 0.34C |

| 3 1/2 | 3.625 | 3.750 | 6.375 | 6.625 | 0.24C | 0.34C |

| 3 3/4 | 3.875 | 4.000 | 6.875 | 7.125 | 0.24C | 0.34C |

| 4 | 4.125 | 4.250 | 7.375 | 7.625 | 0.24C | 0.34C |

| Washer Dimensional Tolerences (Table 4) | ||||

|---|---|---|---|---|

| Dimensional Characteristics | <1 in. Nominal Size | 1 through 1 1⁄2 in. Nominal Size | >1 1⁄2 through 3 in. Nominal Size | >3 in. Nominal Size |

| Flatness: max deviation from straightedge placed on cut side shall not exceed (in.) | 0.010 | 0.015 | 0.020 | 0.032 |

| Concentricity, in.: center of hole to outside diameter | 0.030 FIRA | 0.060 FIRA | 0.090 FIRA | 0.032 FIRA |

| Burr shall not project above immediately adjacent washer surface more than (in.) | 0.010 | 0.015 | 0.020 | 0.025 |

ASTM F436/F436M-19 Standard does not provide any tables about coatings. However, Section 4.3 Cover the different requirements about coatings.

4.3 Protective Coatings:

4.3.1 Unless otherwise specified, washers shall be furnished “plain” with the “as-fabricated” surface finish without protective coatings.

4.3.2 When zinc-coated washers are required, the purchaser shall specify the zinc coating process, for example, hot-dip, mechanically deposited, Zinc/Aluminum Corrosion Protective Coating, or no preference.

4.3.2.1 When hot-dip is specified the washers shall be zinc coated by the hot-dip process in accordance with the requirements of Specification F2329.

4.3.2.2 When thermo-diffusion is specified the washers shall be zinc coated by the thermo-diffusion process in accordance with the requirements of Class 25 of Specification A1059.

4.3.2.3 When mechanically deposited is specified the washers shall be zinc coated by the mechanical-deposition process in accordance with the requirements of Class 55 of Specification B695.

4.3.2.4 When Zinc/Aluminum Corrosion Protective Coating is specified, the washers shall be coated in accordance with the requirements of Grade 3 of Specification F1136/F1136M.

4.3.3 When the zinc coating process is not specified, the supplier may furnish zinc coated washers in accordance with the supplier’s choice of process from 4.3.2.1 through 4.3.2.4.

4.4 If washers are heat treated by a subcontractor, they shall be returned to the manufacturer for testing prior to shipment to the purchaser.

| Chemical RequirementsA | ||

|---|---|---|

| Element | Compositions, % | |

| Type 1 | Type 3B | |

| Phosphorus, max | ||

| –Heat analysis | 0.040 | 0.040 |

| –Product analysis | 0.050 | 0.045 |

| Sulfur, max | ||

| –Heat analysis | 0.050 | 0.050 |

| –Product analysis | 0.060 | 0.055 |

| Silicon | ||

| –Heat analysis | — | 0.15 – 0.35 |

| –Product analysis | — | 0.13 – 0.37 |

| Chromium | ||

| –Heat analysis | — | 0.45 – 0.65 |

| –Product analysis | — | 0.42 – 0.68 |

| Nickel | ||

| –Heat analysis | — | 0.25 – 0.45 |

| –Product analysis | — | 0.22 – 0.48 |

| Copper | ||

| –Heat analysis | — | 0.25 – 0.45 |

| –Product analysis | — | 0.22 – 0.48 |

ASTM F436/F436M-19 does not provide any tables on Mechanical Properties. However, section 6 cover this specification.

6. Mechanical Properties

6.1 Through hardened washers shall have a hardness of 38 to 45 HRC, except when zinc-coated by the hot-dip process, in which case they shall have a hardness of 26 to 45 HRC.

6.2 Carburized washers shall be carburized to a minimum depth of 0.015 in. (inch series) or 0.38 mm (metric series) and shall have a surface hardness of 69 to 73 HRA or 79 to 83 HR15N, except when zinc-coated by the hot-dip process, in which case they shall have a hardness of 63 to 73 HRA or 73 to 83 HR15N.

6.3 Carburized and hardened washers shall have a minimum core hardness of 30 HRC or 65 HRA.

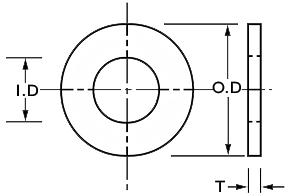

ASTM F436 Extra Thick Flat Washers are essential in structural applications, specifically designed to address unique demands. With thickness exceeding standard specifications, these washers provide enhanced load distribution and durability in bolted joints. Commonly used in applications requiring increased bearing surface or compensating for irregularities, their robust design proves beneficial in scenarios where standard washers may not provide sufficient support. The extra thickness minimizes the risk of deformation and surface damage, ensuring a secure and stable connection. Whether in heavy machinery, infrastructure projects, or industrial applications, ASTM F436 Extra Thick Flat Washers offer a reliable solution, surpassing regular washers in situations demanding heightened load-bearing capabilities and resilience.

*For Weather resistance, see Type 3 products

| ASTM F436 Thick Washer Dimensionals | ||||||

|---|---|---|---|---|---|---|

| Nominal WasherD Size Inch | Inside Diam. (ID) | Outside Diam. (OD) | Thickness (T) | |||

| min | max | min | max | min | max | |

| 1/2 | 0.531 | 0.563 | 1.031 | 1.095 | 0.305 | 0.375 |

| 9/16 | 0.625 | 0.657 | 1.156 | 1.220 | 0.305 | 0.375 |

| 5/8 | 0.688 | 0.720 | 1.281 | 1.345 | 0.305 | 0.375 |

| 3/4 | 0.813 | 0.845 | 1.436 | 1.500 | 0.305 | 0.375 |

| 7/8 | 0.938 | 0.970 | 1.718 | 1.782 | 0.305 | 0.375 |

| 1 | 1.063 | 1.126 | 1.937 | 2.063 | 0.305 | 0.375 |

| 1 1/8 | 1.188 | 1.251 | 2.187 | 2.313 | 0.305 | 0.375 |

| 1 1/4 | 1.375 | 1.438 | 2.437 | 2.563 | 0.305 | 0.375 |

| 1 3/8 | 1.500 | 1.563 | 2.687 | 2.813 | 0.305 | 0.375 |

| 1 1/2 | 1.625 | 1.688 | 2.937 | 3.063 | 0.305 | 0.375 |

| 1 3/4 | 1.875 | 1.938 | 3.312 | 3.438 | 0.305 | 0.375 |

| 2 | 2.125 | 2.188 | 3.687 | 3.813 | 0.305 | 0.375 |

| 2 1/4 | 2.375 | 2.438 | 3.937 | 4.063 | 0.305 | 0.375 |

| 2 1/2 | 2.625 | 2.688 | 4.437 | 4.563 | 0.313 | 0.375 |

| 2 3/4 | 2.875 | 2.938 | 4.937 | 5.063 | 0.313 | 0.375 |

| 3 | 3.125 | 3.188 | 5.437 | 5.563 | 0.313 | 0.375 |

| 3 1/4 | 3.375 | 3.500 | 5.875 | 6.125 | 0.313 | 0.375 |

| 3 1/2 | 3.625 | 3.750 | 6.375 | 6.625 | 0.313 | 0.375 |

| 3 3/4 | 3.875 | 4.000 | 6.875 | 7.125 | 0.313 | 0.375 |

| 4 | 4.125 | 4.250 | 7.375 | 7.625 | 0.313 | 0.375 |

| Washer Dimensional Tolerences (Table 4) | ||||

|---|---|---|---|---|

| Dimensional Characteristics | <1 in. Nominal Size | 1 through 1 1⁄2 in. Nominal Size | >1 1⁄2 through 3 in. Nominal Size | >3 in. Nominal Size |

| Flatness: max deviation from straightedge placed on cut side shall not exceed (in.) | 0.010 | 0.015 | 0.020 | 0.032 |

| Concentricity, in.: center of hole to outside diameter | 0.030 FIRA | 0.060 FIRA | 0.090 FIRA | 0.032 FIRA |

| Burr shall not project above immediately adjacent washer surface more than (in.) | 0.010 | 0.015 | 0.020 | 0.025 |

ASTM F436/F436M-19 Standard does not provide any tables about coatings. However, Section 4.3 Cover the different requirements about coatings.

4.3 Protective Coatings:

4.3.1 Unless otherwise specified, washers shall be furnished “plain” with the “as-fabricated” surface finish without protective coatings.

4.3.2 When zinc-coated washers are required, the purchaser shall specify the zinc coating process, for example, hot-dip, mechanically deposited, Zinc/Aluminum Corrosion Protective Coating, or no preference.

4.3.2.1 When hot-dip is specified the washers shall be zinc coated by the hot-dip process in accordance with the requirements of Specification F2329.

4.3.2.2 When thermo-diffusion is specified the washers shall be zinc coated by the thermo-diffusion process in accordance with the requirements of Class 25 of Specification A1059.

4.3.2.3 When mechanically deposited is specified the washers shall be zinc coated by the mechanical-deposition process in accordance with the requirements of Class 55 of Specification B695.

4.3.2.4 When Zinc/Aluminum Corrosion Protective Coating is specified, the washers shall be coated in accordance with the requirements of Grade 3 of Specification F1136/F1136M.

4.3.3 When the zinc coating process is not specified, the supplier may furnish zinc coated washers in accordance with the supplier’s choice of process from 4.3.2.1 through 4.3.2.4.

4.4 If washers are heat treated by a subcontractor, they shall be returned to the manufacturer for testing prior to shipment to the purchaser.

| Chemical RequirementsA | ||

|---|---|---|

| Element | Compositions, % | |

| Type 1 | Type 3B | |

| Phosphorus, max | ||

| –Heat analysis | 0.040 | 0.040 |

| –Product analysis | 0.050 | 0.045 |

| Sulfur, max | ||

| –Heat analysis | 0.050 | 0.050 |

| –Product analysis | 0.060 | 0.055 |

| Silicon | ||

| –Heat analysis | — | 0.15 – 0.35 |

| –Product analysis | — | 0.13 – 0.37 |

| Chromium | ||

| –Heat analysis | — | 0.45 – 0.65 |

| –Product analysis | — | 0.42 – 0.68 |

| Nickel | ||

| –Heat analysis | — | 0.25 – 0.45 |

| –Product analysis | — | 0.22 – 0.48 |

| Copper | ||

| –Heat analysis | — | 0.25 – 0.45 |

| –Product analysis | — | 0.22 – 0.48 |

ASTM F436/F436M-19 does not provide any tables on Mechanical Properties. However, section 6 cover this specification.

6. Mechanical Properties

6.1 Through hardened washers shall have a hardness of 38 to 45 HRC, except when zinc-coated by the hot-dip process, in which case they shall have a hardness of 26 to 45 HRC.

6.2 Carburized washers shall be carburized to a minimum depth of 0.015 in. (inch series) or 0.38 mm (metric series) and shall have a surface hardness of 69 to 73 HRA or 79 to 83 HR15N, except when zinc-coated by the hot-dip process, in which case they shall have a hardness of 63 to 73 HRA or 73 to 83 HR15N.

6.3 Carburized and hardened washers shall have a minimum core hardness of 30 HRC or 65 HRA.

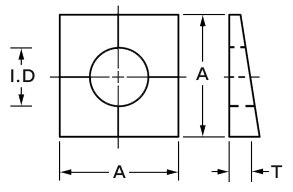

ASTM F436 Beveled Washers, Types 1 and 3, are pivotal in structural applications, offering specialized solutions for specific needs. Crafted from medium carbon steel and weathering steel, respectively, their unique beveled design aids alignment and load distribution in bolted joints. Ideal for applications requiring smooth surface transitions, these washers reduce stress concentrations, ensuring stability. With high hardness and corrosion resistance, they excel in diverse projects, aligning with ASTM F436 standards for stringent chemical and mechanical specifications, making beveled washers a preferred choice over flat washers in situations demanding precise surface interaction and enhanced joint stability.

*For Weather resistance, see Type 3 products

| ASTM F436 Beveled Washer Dimensionals | ||||||

|---|---|---|---|---|---|---|

| Bolt Size, in. | Side Dim. (A) | Nominal Inside Diam. (ID), in. | Mean Thickness (T), in. | Slope or Taper Thickness | ||

| min | max | min | max | |||

| 1/2 | 1.718 | 1.782 | 0.531 | 0.563 | 0.312 | 1:6 |

| 5/8 | 1.718 | 1.782 | 0.688 | 0.720 | 0.312 | 1:6 |

| 3/4 | 1.718 | 1.782 | 0.812 | 0.844 | 0.312 | 1:6 |

| 7/8 | 1.718 | 1.782 | 0.938 | 0.970 | 0.312 | 1:6 |

| 1 | 2.187 | 2.313 | 1.125 | 1.188 | 0.312 | 1:6 |

| 1 1/8 | 2.187 | 2.313 | 1.250 | 1.313 | 0.312 | 1:6 |

| 1 1/4 | 2.187 | 2.313 | 1.380 | 1.443 | 0.312 | 1:6 |

| 1 3/8 | 2.187 | 2.313 | 1.500 | 1.563 | 0.312 | 1:6 |

| 1 1/2 | 2.187 | 2.313 | 1.625 | 1.688 | 0.312 | 1:6 |

| Washer Dimensional Tolerences (Table 4) | ||||

|---|---|---|---|---|

| Dimensional Characteristics | <1 in. Nominal Size | 1 through 1 1⁄2 in. Nominal Size | >1 1⁄2 through 3 in. Nominal Size | >3 in. Nominal Size |

| Flatness: max deviation from straightedge placed on cut side shall not exceed (in.) | 0.010 | 0.015 | 0.020 | 0.032 |

| Concentricity, in.: center of hole to outside diameter | 0.030 FIRA | 0.060 FIRA | 0.090 FIRA | 0.032 FIRA |

| Burr shall not project above immediately adjacent washer surface more than (in.) | 0.010 | 0.015 | 0.020 | 0.025 |

ASTM F436/F436M-19 Standard does not provide any tables about coatings. However, Section 4.3 Cover the different requirements about coatings.

4.3 Protective Coatings:

4.3.1 Unless otherwise specified, washers shall be furnished “plain” with the “as-fabricated” surface finish without protective coatings.

4.3.2 When zinc-coated washers are required, the purchaser shall specify the zinc coating process, for example, hot-dip, mechanically deposited, Zinc/Aluminum Corrosion Protective Coating, or no preference.

4.3.2.1 When hot-dip is specified the washers shall be zinc coated by the hot-dip process in accordance with the requirements of Specification F2329.

4.3.2.2 When thermo-diffusion is specified the washers shall be zinc coated by the thermo-diffusion process in accordance with the requirements of Class 25 of Specification A1059.

4.3.2.3 When mechanically deposited is specified the washers shall be zinc coated by the mechanical-deposition process in accordance with the requirements of Class 55 of Specification B695.

4.3.2.4 When Zinc/Aluminum Corrosion Protective Coating is specified, the washers shall be coated in accordance with the requirements of Grade 3 of Specification F1136/F1136M.

4.3.3 When the zinc coating process is not specified, the supplier may furnish zinc coated washers in accordance with the supplier’s choice of process from 4.3.2.1 through 4.3.2.4.

4.4 If washers are heat treated by a subcontractor, they shall be returned to the manufacturer for testing prior to shipment to the purchaser.

| Chemical RequirementsA | ||

|---|---|---|

| Element | Compositions, % | |

| Type 1 | Type 3B | |

| Phosphorus, max | ||

| –Heat analysis | 0.040 | 0.040 |

| –Product analysis | 0.050 | 0.045 |

| Sulfur, max | ||

| –Heat analysis | 0.050 | 0.050 |

| –Product analysis | 0.060 | 0.055 |

| Silicon | ||

| –Heat analysis | — | 0.15 – 0.35 |

| –Product analysis | — | 0.13 – 0.37 |

| Chromium | ||

| –Heat analysis | — | 0.45 – 0.65 |

| –Product analysis | — | 0.42 – 0.68 |

| Nickel | ||

| –Heat analysis | — | 0.25 – 0.45 |

| –Product analysis | — | 0.22 – 0.48 |

| Copper | ||

| –Heat analysis | — | 0.25 – 0.45 |

| –Product analysis | — | 0.22 – 0.48 |

ASTM F436/F436M-19 does not provide any tables on Mechanical Properties. However, section 6 cover this specification.

6. Mechanical Properties

6.1 Through hardened washers shall have a hardness of 38 to 45 HRC, except when zinc-coated by the hot-dip process, in which case they shall have a hardness of 26 to 45 HRC.

6.2 Carburized washers shall be carburized to a minimum depth of 0.015 in. (inch series) or 0.38 mm (metric series) and shall have a surface hardness of 69 to 73 HRA or 79 to 83 HR15N, except when zinc-coated by the hot-dip process, in which case they shall have a hardness of 63 to 73 HRA or 73 to 83 HR15N.

6.3 Carburized and hardened washers shall have a minimum core hardness of 30 HRC or 65 HRA.