ASTM F3125 Grade A325 fasteners are high-strength structural bolts designed for heavy-duty applications in construction and engineering. Known for their durability and reliability, these bolts provide a secure and robust connection in structural steel joints. With stringent manufacturing standards, Grade A325 bolts offer exceptional tensile strength of up to 120 ksi and weather resistance*. Ideal for use in critical structural elements, they ensure the integrity and safety of constructions.

*For Weather resistance, see Type 3 products

** Please take note that Boulons Plus only sell pre-assembled sets including 1 bolt, 1 washer and 1 nut.

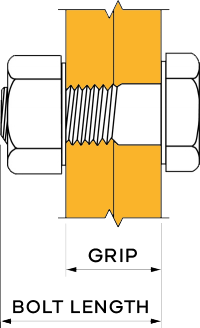

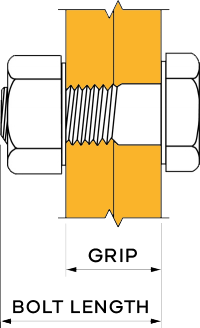

Facilitating the selection of bolt length for a specific grip and bolt diameter is simplified by referring to the “Bolt Lengths for Various Grips” chart on page 6-167 in the Handbook of Steel Construction, 11th edition. This chart is relevant to the Imperial Series of ASTM F3125/F3125M bolts, including Grades A325/F1852 and A490/F2280 high-strength bolts used in bearing-type and slip-critical connections. It’s important to note that the provided bolt lengths may not automatically exclude bolt threads from the shear plane(s).

| Grip Inches | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1/2 | 5/8 | 3/4 | 7/8 | 1 | 1 1/8 | 1 1/4 | 1 3/8 | 1 1/2 | |

| 3/4 | 1 1/2 | 1 3/4 | *** | 2 | *** | *** | 2 1/2 | *** | 2 3/4 |

| 13/16 | 1 1/2 | 1 3/4 | 2 | 2 | 2 1/4 | 2 1/2 | 2 1/2 | 2 3/4 | 2 3/4 |

| 7/8 | 1 3/4 | 1 3/4 | 2 | 2 | 2 1/4 | 2 1/2 | 2 1/2 | 2 3/4 | 2 3/4 |

| 15/16 | 1 3/4 | 2 | 2 | 2 1/4 | 2 1/4 | 2 1/2 | 2 3/4 | 2 3/4 | 3 |

| 1 | 1 3/4 | 2 | 2 | 2 1/4 | 2 1/4 | 2 1/2 | 2 3/4 | 2 3/4 | 3 |

| 1 1/16 | 1 3/4 | 2 | 2 1/4 | 2 1/4 | 2 1/2 | 2 3/4 | 2 3/4 | 3 | 3 |

| 1 1/8 | 2 | 2 | 2 1/4 | 2 1/4 | 2 1/2 | 2 3/4 | 2 3/4 | 3 | 3 |

| 1 3/16 | 2 | 2 1/4 | 2 1/4 | 2 1/2 | 2 1/2 | 2 3/4 | 3 | 3 | 3 1/4 |

| 1 1/4 | 2 | 2 1/4 | 2 1/4 | 2 1/2 | 2 1/2 | 2 3/4 | 3 | 3 | 3 1/4 |

| 1 5/16 | 2 | 2 1/4 | 2 1/2 | 2 1/2 | 2 3/4 | 3 | 3 | 3 1/4 | 3 1/4 |

| 1 3/8 | 2 1/4 | 2 1/4 | 2 1/2 | 2 1/2 | 2 3/4 | 3 | 3 | 3 1/4 | 3 1/4 |

| 1 7/16 | 2 1/4 | 2 1/2 | 2 1/2 | 2 3/4 | 2 3/4 | 3 | 3 1/4 | 3 1/4 | 3 1/2 |

| 1 1/2 | 2 1/4 | 2 1/2 | 2 1/2 | 2 3/4 | 2 3/4 | 3 | 3 1/4 | 3 1/4 | 3 1/2 |

| 1 9/16 | 2 1/4 | 2 1/2 | 2 3/4 | 3 3/4 | 3 | 3 1/4 | 3 1/4 | 3 1/2 | 3 1/2 |

| 1 5/8 | 2 1/2 | 2 1/2 | 2 3/4 | 2 3/4 | 3 | 3 1/4 | 3 1/4 | 3 1/2 | 3 1/2 |

| 1 11/16 | 2 1/2 | 2 3/4 | 2 3/4 | 3 | 3 | 3 1/4 | 3 1/2 | 3 1/2 | 3 3/4 |

| 1 3/4 | 2 1/2 | 2 3/4 | 2 3/4 | 3 | 3 | 3 1/4 | 3 1/2 | 3 1/2 | 3 3/4 |

| 1 13/16 | 2 1/2 | 2 3/4 | 3 | 3 | 3 1/4 | 3 1/2 | 3 1/2 | 3 3/4 | 3 3/4 |

| 1 7/8 | 2 3/4 | 2 3/4 | 3 | 3 | 3 1/4 | 3 1/2 | 3 1/2 | 3 3/4 | 3 3/4 |

| 1 15/16 | 2 3/4 | 3 | 3 | 3 1/4 | 3 1/4 | 3 1/2 | 3 3/4 | 3 3/4 | 4 |

| 2 | 2 3/4 | 3 | 3 | 3 1/4 | 3 1/4 | 3 1/2 | 3 3/4 | 3 3/4 | 4 |

| 2 1/16 | 2 3/4 | 3 | 3 1/4 | 3 1/4 | 3 1/2 | 3 3/4 | 3 3/4 | 4 | 4 |

| 2 1/8 | 3 | 3 | 3 1/4 | 3 1/4 | 3 1/2 | 3 3/4 | 3 3/4 | 4 | 4 |

| 2 3/16 | 3 | 3 1/4 | 3 1/4 | 3 1/2 | 3 1/2 | 3 3/4 | 4 | 4 | 4 1/4 |

| 2 1/4 | 3 | 3 1/4 | 3 1/4 | 3 1/2 | 3 1/2 | 3 3/4 | 4 | 4 | 4 1/4 |

| 2 5/16 | 3 | 3 1/4 | 3 1/2 | 3 1/2 | 3 3/4 | 4 | 4 | 4 1/4 | 4 1/4 |

| 2 3/8 | 3 1/4 | 3 1/4 | 3 1/2 | 3 1/2 | 3 3/4 | 4 | 4 | 4 1/4 | 4 1/4 |

| 2 7/16 | 3 1/4 | 3 1/2 | 3 1/2 | 3 3/4 | 3 3/4 | 4 | 4 1/4 | 4 1/4 | 4 1/2 |

| 2 1/2 | 3 1/4 | 3 1/2 | 3 1/2 | 3 3/4 | 3 3/4 | 4 | 4 1/4 | 4 1/4 | 4 1/2 |

| 2 9/16 | 3 1/4 | 3 1/2 | 3 3/4 | 3 3/4 | 4 | 4 1/4 | 4 1/4 | 4 1/2 | 4 1/2 |

| 2 5/8 | 3 1/2 | 3 1/2 | 3 3/4 | 3 3/4 | 4 | 4 1/4 | 41/4 | 4 1/2 | 4 1/2 |

| 2 11/16 | 3 1/2 | 3 3/4 | 3 3/4 | 4 | 4 | 4 1/4 | 4 1/2 | 4 1/2 | 4 3/4 |

| 2 3/4 | 3 1/2 | 3 3/4 | 3 3/4 | 4 | 4 | 4 1/4 | 4 1/2 | 4 1/2 | 4 3/4 |

| 2 13/16 | 3 1/2 | 3 3/4 | 4 | 4 | 4 1/4 | 4 1/2 | 4 1/2 | 4 3/4 | 4 3/4 |

| 2 7/8 | 3 3/4 | 3 3/4 | 4 | 4 | 4 1/4 | 4 1/2 | 4 1/2 | 4 3/4 | 4 3/4 |

| 2 15/16 | 3 3/4 | 4 | 4 | 4 1/4 | 4 1/4 | 4 1/2 | 4 3/4 | 4 3/4 | 5 |

| 3 | 3 3/4 | 4 | 4 | 4 1/4 | 4 1/4 | 4 1/2 | 4 3/4 | 4 3/4 | 5 |

| 3 1/16 | 3 3/4 | 4 | 4 1/4 | 4 1/4 | 4 1/2 | 4 3/4 | 4 3/4 | 5 | 5 |

| 3 1/8 | 4 | 4 | 4 1/4 | 4 1/4 | 4 1/2 | 4 3/4 | 4 3/4 | 5 | 5 |

| 3 3/16 | 4 | 4 1/4 | 4 1/4 | 4 1/2 | 4 1/2 | 4 3/4 | 5 | 5 | 5 1/4 |

| 3 1/4 | 4 | 4 1/4 | 4 1/4 | 4 1/2 | 4 1/2 | 4 3/4 | 5 | 5 | 5 1/4 |

| 3 5/16 | 4 | 4 1/4 | 4 1/2 | 4 1/2 | 4 3/4 | 5 | 5 | 5 1/4 | 5 1/4 |

| 3 3/8 | 4 1/4 | 4 1/4 | 4 1/2 | 4 1/2 | 4 3/4 | 5 | 5 | 5 1/4 | 5 1/4 |

| 3 7/16 | 4 1/4 | 4 1/2 | 4 1/2 | 4 3/4 | 4 3/4 | 5 | 5 1/4 | 5 1/4 | 5 1/2 |

| 3 1/2 | 4 1/4 | 4 1/2 | 4 1/2 | 4 3/4 | 4 3/4 | 5 | 5 1/4 | 5 1/4 | 5 1/2 |

| 3 9/16 | 4 1/4 | 4 1/2 | 4 3/4 | 4 3/4 | 5 | 5 1/4 | 5 1/4 | 5 1/2 | 5 1/2 |

| 3 5/8 | 4 1/2 | 4 1/2 | 4 3/4 | 4 3/4 | 5 | 5 1/4 | 5 1/4 | 5 1/2 | 5 1/2 |

| 3 11/16 | 4 1/2 | 4 3/4 | 4 3/4 | 5 | 5 | 5 1/4 | 5 1/2 | 5 1/2 | 5 3/4 |

| 3 3/4 | 4 1/2 | 4 3/4 | 4 3/4 | 5 | 5 | 5 1/4 | 5 1/2 | 5 1/2 | 5 3/4 |

| 3 13/16 | 4 1/2 | 4 3/4 | 5 | 5 | 5 1/4 | 5 1/2 | 5 1/2 | 5 3/4 | 5 3/4 |

| 3 7/8 | 4 3/4 | 4 3/4 | 5 | 5 | 5 1/4 | 5 1/2 | 5 1/2 | 5 3/4 | 5 3/4 |

| 3 15/16 | 4 3/4 | 5 | 5 | 5 1/4 | 5 1/4 | 5 1/2 | 5 3/4 | 5 3/4 | 6 |

| 4 | 4 3/4 | 5 | 5 | 5 1/4 | 5 1/2 | 5 1/2 | 5 3/4 | 5 3/4 | 6 |

| 4 1/16 | 4 3/4 | 5 | 5 1/4 | 5 1/4 | 5 1/2 | 5 3/4 | 5 3/4 | 6 | 6 |

| Bolt Diam. | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Body Diam. | Width Across Flat | Width Across Corners | Head Height | Thread Length | ||||||

| Max | Basic | Max | Min | Max | Min | Basic | Max | Min | Basic | |

| 1/2-13 | 0.515 | 7/8 | 0.875 | 0.850 | 1.010 | 0.969 | 5/16 | 0.323 | 0.302 | 1.00 |

| 5/8-11 | 0.642 | 1 1/16 | 1.062 | 1.031 | 1.227 | 1.175 | 25/64 | 0.403 | 0.378 | 1.25 |

| 3/4-10 | 0.768 | 1 1/4 | 1.250 | 1.212 | 1.443 | 1.383 | 15/32 | 0.483 | 0.455 | 1.38 |

| 7/8-9 | 0.895 | 1 7/16 | 1.438 | 1.394 | 1.660 | 1.589 | 35/64 | 0.563 | 0.531 | 1.50 |

| 1-8 | 1.022 | 1 5/8 | 1.625 | 1.575 | 1.876 | 1.796 | 39/64 | 0.627 | 0.591 | 1.75 |

| 1 1/8-7 | 1.149 | 1 13/16 | 1.812 | 1.756 | 2.093 | 2.002 | 11/16 | 0.718 | 0.658 | 2.00 |

| 1 1/4-7 | 1.277 | 2 | 2.00 | 1.938 | 2.309 | 2.209 | 25/32 | 0.813 | 0.749 | 2.00 |

| 1 3/8-6 | 1.404 | 2 3/16 | 2.188 | 2.119 | 2.526 | 2.416 | 27/32 | 0.878 | 0.810 | 2.25 |

| 1 1/2-6 | 1.531 | 2 3/8 | 2.375 | 2.300 | 2.742 | 2.622 | 15/16 | 0.974 | 0.902 | 2.25 |

| F3125 Grade A325 Dimensions, Threads & Grade Marking | ||

|---|---|---|

| Type 1 | Type 3 | |

| Style – Heavy Hex Bolts | ||

| Dimensions, ASMEB | B18.2.6 | B18.2.6 |

| Thread Fit, ASMEB | B1.1 UNC 2A | B1.1 UNC 2A |

| Grade MarkingA, D | A325 | A325 |

| F3125 Gr.A325 & F1852 Matching Components | ||

|---|---|---|

| Type 1 | Type 3 | |

| Recommended Nut and Washer | ||

| Plain Nut | A563 DH | A563 DH3 |

| Suitable AlternativeE | DH3, D, C, C3 | C3 |

| Coated Nut | A563 DH | A563 DH3 |

| Flat, Bevel or Thick washer if used | F436-1 | F436-3 |

| 120 ksi Bolt AssembliesA | |||

|---|---|---|---|

| Commonly Applied Coatings | Grade or Class | ||

| F2329 | Hot Dip Galvanized / 50 μm | ||

| B695 | Class 55 | ||

| Other Coatings | Classification codes | ||

| Corrosion | Appearance | Coefficient of friction | |

| F3393 | D | 1 | RB |

Features | F3125 KPF | F3125 Domestic |

|---|---|---|

Keg Material | Metal | Plastic |

Keg Max Weight | 65 Lbs | 95 Lbs |

Come With Handle | ✔ | ✔ |

Quickly Open/Seal Lid | ✔ | ✔ |

Kegs Per Skid | 27 | 18 |

Keg Height | 8 1/4 inches | 11 inches |

Keg Visual |  |  |

| DIAM: 1/2 | ||||

|---|---|---|---|---|

| LENGTH | BOLTS/KEG | Lbs/KEG | BOLTS/KEG | Lbs/KEG |

| 1 1/4 | 270 | 59 | 450 | 92 |

| 1 1/2 | 250 | 115 | 400 | 80 |

| 1 3/4 | 240 | 115 | 350 | 81 |

| 2 | 240 | 125 | 350 | 86 |

| 2 1/4 | 230 | 62 | 325 | 85 |

| 2 1/2 | 220 | 62 | 300 | 83 |

| 2 3/4 | 210 | 63 | 275 | 80 |

| 3 | 200 | 62 | 265 | 81 |

| 3 1/4 | 190 | 62 | 250 | 80 |

| 3 1/2 | 180 | 61 | 240 | 80 |

| 3 3/4 | 170 | 60 | 215 | 75 |

| 4 | 160 | 59 | 200 | 73 |

| 4 1/4 | N/A | N/A | 200 | 75 |

| 4 1/2 | N/A | N/A | 190 | 74 |

| 4 3/4 | N/A | N/A | 175 | 71 |

| 5 | N/A | N/A | 150 | 63 |

| DIAM: 5/8 | ||||

|---|---|---|---|---|

| LENGTH | BOLTS/KEG | LBS/KEG | BOLTS/KEG | LBS/KEG |

| 1 1/2 | 150 | 56 | 250 | 94 |

| 1 3/4 | 140 | 55 | 250 | 100 |

| 2 | 140 | 58 | 225 | 95 |

| 2 1/4 | 130 | 57 | 200 | 89 |

| 2 1/2 | 130 | 60 | 200 | 93 |

| 2 3/4 | 120 | 58 | 175 | 85 |

| 3 | 120 | 60 | 165 | 84 |

| 3 1/4 | 110 | 58 | 150 | 80 |

| 3 1/2 | 110 | 60 | 150 | 83 |

| 3 3/4 | 100 | 57 | 130 | 75 |

| 4 | 100 | 59 | 130 | 78 |

| 4 1/4 | 90 | 55 | 120 | 75 |

| 4 1/2 | 90 | 57 | 115 | 70 |

| 4 3/4 | 90 | 59 | 115 | 77 |

| 5 | 80 | 55 | 115 | 79 |

| 5 1/4 | 80 | 56 | 110 | 78 |

| 5 1/2 | 80 | 58 | 105 | 77 |

| 5 3/4 | 80 | 59 | 100 | 76 |

| 6 | 70 | 53 | 95 | 74 |

| DIAM: 3/4 | ||||

|---|---|---|---|---|

| LENGTH | BOLTS/KEG | LBS/KEG | BOLTS/KEG | LBS/KEG |

| 1 1/2 | 100 | 59 | 170 | 100 |

| 1 3/4 | 100 | 62 | 150 | 93 |

| 2 | 95 | 62 | 150 | 97 |

| 2 1/4 | 85 | 59 | 135 | 92 |

| 2 1/2 | 90 | 65 | 130 | 93 |

| 2 3/4 | 85 | 64 | 125 | 93 |

| 3 | 80 | 63 | 115 | 89 |

| 3 1/4 | 75 | 61 | 110 | 89 |

| 3 1/2 | 80 | 68 | 105 | 88 |

| 3 3/4 | 70 | 62 | 100 | 87 |

| 4 | 70 | 64 | 95 | 86 |

| 4 1/4 | 60 | 57 | 85 | 80 |

| 4 1/2 | 60 | 59 | 85 | 83 |

| 4 3/4 | 55 | 56 | 75 | 75 |

| 5 | 55 | 58 | 75 | 78 |

| 5 1/4 | 55 | 59 | 65 | 70 |

| 5 1/2 | 55 | 61 | 65 | 72 |

| 5 3/4 | 50 | 55 | 65 | 73 |

| 6 | 50 | 59 | 65 | 76 |

| 6 1/4 | 50 | 60 | 60 | 72 |

| 6 1/2 | 50 | 62 | 60 | 74 |

| 6 3/4 | 45 | 56 | 55 | 70 |

| 7 | 45 | 59 | 55 | 72 |

| 7 1/2 | 45 | 60 | 50 | 68 |

| 8 | 40 | 57 | 45 | 64 |

| 8 1/2 | 40 | 58 | 40 | 67 |

| DIAM: 7/8 | ||||

|---|---|---|---|---|

| LENGTH | BOLTS/KEG | LBS/KEG | BOLTS/KEG | LBS/KEG |

| 1 3/4 | 60 | 53 | 110 | 100 |

| 2 | 60 | 56 | 100 | 95 |

| 2 1/4 | 60 | 59 | 95 | 95 |

| 2 1/2 | 55 | 56 | 90 | 94 |

| 2 3/4 | 55 | 58 | 85 | 92 |

| 3 | 50 | 55 | 80 | 90 |

| 3 1/4 | 50 | 57 | 75 | 88 |

| 3 1/2 | 50 | 59 | 75 | 91 |

| 3 3/4 | 45 | 56 | 70 | 89 |

| 4 | 45 | 57 | 65 | 85 |

| 4 1/4 | 45 | 59 | 60 | 81 |

| 4 1/2 | 40 | 54 | 60 | 83 |

| 4 3/4 | 40 | 56 | 55 | 79 |

| 5 | 40 | 58 | 55 | 82 |

| 5 1/4 | 40 | 59 | 50 | 76 |

| 5 1/2 | 40 | 61 | 50 | 79 |

| 5 3/4 | 35 | 55 | 45 | 73 |

| 6 | 35 | 56 | 45 | 75 |

| DIAM: 1 | ||||

|---|---|---|---|---|

| LENGTH | BOLTS/KEG | LBS/KEG | BOLTS/KEG | LBS/KEG |

| 2 | 45 | 58 | 75 | 99 |

| 2 1/4 | 45 | 60 | 70 | 96 |

| 2 1/2 | 40 | 56 | 70 | 100 |

| 2 3/4 | 40 | 58 | 65 | 96 |

| 3 | 40 | 60 | 60 | 93 |

| 3 1/4 | 35 | 54 | 60 | 96 |

| 3 1/2 | 35 | 56 | 55 | 91 |

| 3 3/4 | 35 | 58 | 55 | 94 |

| 4 | 35 | 60 | 50 | 88 |

| 4 1/4 | 35 | 62 | 45 | 82 |

| 4 1/2 | 30 | 55 | 45 | 84 |

| 4 3/4 | 30 | 57 | 40 | 78 |

| 5 | 30 | 58 | 40 | 80 |

| 5 1/4 | 30 | 60 | 40 | 82 |

| 5 1/2 | 30 | 62 | 30 | 64 |

| 5 3/4 | 25 | 53 | 35 | 76 |

| 6 | 25 | 54 | 30 | 67 |

| 6 1/4 | 25 | 55 | 30 | 69 |

| 6 1/2 | 25 | 57 | 30 | 71 |

| DIAM: 1 1/8 | ||||

|---|---|---|---|---|

| LENGTH | BOLTS/KEG | LBS/KEG | BOLTS/KEG | LBS/KEG |

| 2 3/4 | 30 | 58 | 50 | 99 |

| 3 | 30 | 60 | 45 | 92 |

| 3 1/4 | 30 | 62 | 45 | 95 |

| 3 1/2 | 25 | 53 | 40 | 87 |

| 3 3/4 | 25 | 55 | 40 | 90 |

| 4 | 25 | 57 | 40 | 93 |

| 4 1/4 | 25 | 59 | 35 | 84 |

| 4 1/2 | 25 | 60 | 35 | 87 |

| 4 3/4 | 20 | 50 | 30 | 77 |

| 5 | 20 | 51 | 30 | 79 |

| 5 1/4 | 20 | 52 | 30 | 81 |

| 5 1/2 | 20 | 54 | 25 | 70 |

| 5 3/4 | 20 | 55 | 25 | 71 |

| 6 | 20 | 57 | 25 | 73 |

| 6 1/4 | 20 | 58 | 25 | 75 |

| 6 1/2 | 20 | 59 | 25 | 77 |

| 6 3/4 | 15 | 56 | 25 | 78 |

| 7 | 15 | 47 | 25 | 80 |

| 7 1/4 | 15 | 48 | 20 | 66 |

| 7 1/2 | 15 | 49 | 20 | 67 |

| DIAM: 1 1/4 | ||||

|---|---|---|---|---|

| LENGTH | BOLTS/KEG | LBS/KEG | BOLTS/KEG | LBS/KEG |

| 2 3/4 | N/A | N/A | 50 | 99 |

| 3 | N/A | N/A | 45 | 92 |

| 3 1/4 | N/A | N/A | 45 | 95 |

| 3 1/2 | N/A | N/A | 40 | 88 |

| 3 3/4 | N/A | N/A | 40 | 90 |

| 4 | N/A | N/A | 40 | 93 |

| 4 1/4 | N/A | N/A | 35 | 84 |

| 4 1/2 | N/A | N/A | 35 | 87 |

| 4 3/4 | N/A | N/A | 30 | 77 |

| 5 | N/A | N/A | 30 | 79 |

| 5 1/4 | N/A | N/A | 30 | 81 |

| 5 1/2 | N/A | N/A | 25 | 70 |

| 5 3/4 | N/A | N/A | 25 | 71 |

| 6 | N/A | N/A | 25 | 73 |

| 6 1/4 | N/A | N/A | 25 | 75 |

| 6 1/2 | N/A | N/A | 25 | 77 |

| 6 3/4 | N/A | N/A | 25 | 78 |

| 7 | N/A | N/A | 25 | 80 |

| 7 1/4 | N/A | N/A | 20 | 66 |

| 7 1/2 | N/A | N/A | 20 | 67 |

| DIAM: 1 1/2 | ||||

|---|---|---|---|---|

| LENGTH | BOLTS/KEG | LBS/KEG | BOLTS/KEG | LBS/KEG |

| 3 1/2 | N/A | N/A | 20 | 90 |

| 3 3/4 | N/A | N/A | 20 | 92 |

| 4 | N/A | N/A | 15 | 72 |

| 4 1/4 | N/A | N/A | 15 | 73 |

| 4 1/2 | N/A | N/A | 15 | 75 |

| 4 3/4 | N/A | N/A | 15 | 77 |

| 5 | N/A | N/A | 15 | 79 |

| 5 1/4 | N/A | N/A | 15 | 81 |

| 5 1/2 | N/A | N/A | 15 | 83 |

| 5 3/4 | N/A | N/A | 15 | 84 |

| 6 | N/A | N/A | 15 | 86 |

| 6 1/4 | N/A | N/A | 10 | 60 |

| 6 1/2 | N/A | N/A | 10 | 61 |

As per Section 16 of ASTM F3125/F3125-23, here’s a summary of the requirements for packaging and package marking of heavy hex bolts and twist-off bolt assemblies.

16. Packaging and Package Marking:

16.1 Packaging:

16.2 Package Marking:

| Gr.A325 & Gr.F1852 Chemical Requirements | ||||

|---|---|---|---|---|

| Heat Analysis | Type 1 | Type 3 | ||

| Carbon or Alloy Steel With Or Without Boron | Composition A | Composition B | Based On Corrosion IndexB | |

| Carbon | 0.30 – 0.52 | 0.33 – 0.40 | 038 – 0.48 | 0.30 – 0.52 max |

| Manganese | 0.60 min | 0.90 – 1.20 | 0.70 – 0.90 | 0.60 min |

| Phosphorus, max | 0.035 | 0.035 | 0.035 | 0.035 |

| Sulfur, max | 0.04 | 0.04 | 0.04 | 0.04 |

| Silicon | 0.15 – 0.30 | 0.15 – 0.30 | 0.30 – 0.50 | D |

| Boron | 0.003 max | D | D | D |

| Copper | D | 0.25 – 0.45 | 0.20 – 0.40 | 0.20 – 0.60 |

| Nickel | D | 0.25 – 0.45 | 0.50 – 0.80 | 0.20E min |

| Chromium | D | 0.45 – 0.65 | 0.50 – 0.75 | 0.45 min |

| Vanadium | D | D | D | D |

| Molybdenum | D | D | 0.06 max | 0.10E min |

| Titanium | D | D | D | D |

| Gr.A325 & Gr.F1852 Mechanical Properties (Full Size Bolts) | ||||

|---|---|---|---|---|

| Diam. | Stress AreaA | Tensile min | Proof Load Length Measurement min | Alternative Proof Load Yield Strength Method min |

| In. | In2 | lbf | lbf | lbf |

| 1/2-13 UNC | 0.142 | 17,050 | 12,050 | 13,050 |

| 5/8-11 UNC | 0.226 | 27,100 | 19,200 | 20,800 |

| 3/4-10 UNC | 0.334 | 40,100 | 28,400 | 30,700 |

| 7/8-9 UNC | 0.462 | 55,450 | 39,250 | 42,500 |

| 1-8 UNC | 0.606 | 72,700 | 51,500 | 55,750 |

| 1 1/8-7 UNC | 0.763 | 91,600B | 64,900B | 70,250B |

| 1 1/4-7 UNC | 0.969 | 116,300B | 82,400B | 89,200B |

| 1 3/8-6 UNC | 1.155 | 138,600B | 98,200B | 106,300B |

| 1 1/2-6 UNC | 1.405 | 168,600B | 119,500B | 129,300B |

| Above values based on | – | 120 Ksi | 85 Ksi | 92 Ksi |

| Gr.A325 & Gr.F1852 Mechanical Properties (Specimen Machined Bolts) | ||||

|---|---|---|---|---|

| Tensile min. | Tensile max. | Yield min. | Elongation in 4D min % | Reduction of Area min % |

| 120 ksi | … | 92 ksi | 14 | 35 |

| Gr.A325 & F1852 Hardness Requirements for bolts | |||

|---|---|---|---|

| Brinell HB | Rockwell HRC | ||

| Min | Max | Min | Max |

| 253 | 319 | 25 | 34 |

| Gr. A325 & Gr.F1852 Pre-tension Requirements by Strength and Diameter | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Bolt Diam. | 1/2 | 5/8 | 3/4 | 7/8 | 1 | 1 1/8 | 1 1/4 | 1 3/8 | 1 1/2 |

| Kip | 1 | 2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 |

| lbf | 1,000 | 2,000 | 3,000 | 4,000 | 5,000 | 6,000 | 8,000 | 10,000 | 12,000 |

| Gr. A325 Min. Tension At Full Rotation | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Bolt Diam. | 1/2 | 5/8 | 3/4 | 7/8 | 1 | 1 1/8 | 1 1/4 | 1 3/8 | 1 1/2 |

| Kip | 14 | 22 | 32 | 45 | 59 | 74 | 94 | 112 | 136 |

| lbf | 14,000 | 22,000 | 32,000 | 45,000 | 59,000 | 74,000 | 94,000 | 112,000 | 136,000 |

| Maximum Permitted Torque For Gr.A325 at Minimum Design TensionA | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Bolt Diam. In. | 1/2 | 5/8 | 3/4 | 7/8 | 1 | 1 1/8 | 1 1/4 | 1 3/8 | 1 1/2 |

| Tension (Kips)A | 12 | 19 | 28 | 39 | 51 | 64 | 81 | 97 | 118 |

| Tension (lbf) | 12,000 | 19,000 | 28,000 | 39,000 | 51,000 | 64,000 | 81,000 | 97,000 | 118,000 |

| Max. Torque Ft.Lbs | 125 | 247 | 437 | 710 | 1,062 | 1,502 | 2,120 | 2,779 | 3,688 |

| Maximum Permitted Torque For Gr.A325 at Minimum Design Tension | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Bolt Diam. In. | 1/2 | 5/8 | 3/4 | 7/8 | 1 | 1 1/8 | 1 1/4 | 1 3/8 | 1 1/2 |

| Torque (Ft.Lbs) | 150 | 290 | 500 | 820 | 1,230 | 1,730 | 2,450 | 3,210 | 4,250 |

| Minimum Required Degrees Of Rotation For Gr.A325 | ||

|---|---|---|

| Up to 4D | >4D to 8D | >8D to 12D |

| 240 | 360 | 420 |

| Minimum Required Degrees of Rotation (A2.5) | ||

|---|---|---|

| Bolt Length | Up to and including 4D | Greater than 4D up to and including 8D |

| Required Rotation (All Grades) | 120 | 180 |

| Minimum Required Degrees of Rotation (A2.7) | ||

|---|---|---|

| Bolt Length | Up to and including 4D | Greater than 4D up to and including 8D |

| Required Rotation (120 ksi) | 120 | 180 |

| LOT SIZE | |||

|---|---|---|---|

| 1-50 | 1 | ||

| 51-280 | 2 | ||

| 281-3,200 | 3 | ||

| 3,201-35,000 | 4 | ||

| 35,001-150,000 | 5 | ||

| 150,001-500,000 | 6 | ||

| 500,001+ | 7 |

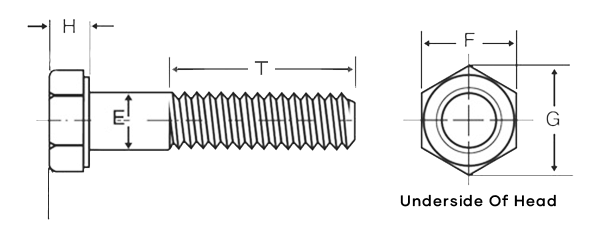

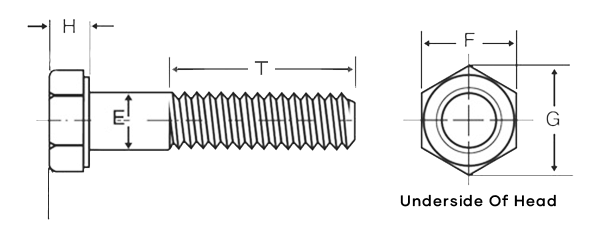

ASTM F3125 Grade F1852 fasteners, designed for use in structural steel connections, are known for their exceptional performance. With a tensile strength of 120 ksi, these bolts are specifically engineered for pre-tensioned structural bolting, offering reliable clamping force. Their installation requires an electric shear wrench, ensuring precise and secure connections in critical applications, such as steel-framed buildings and bridges. The F1852 grade’s robust characteristics make it a preferred choice for demanding construction projects.

Facilitating the selection of bolt length for a specific grip and bolt diameter is simplified by referring to the “Bolt Lengths for Various Grips” chart on page 6-167 in the Handbook of Steel Construction, 11th edition. This chart is relevant to the Imperial Series of ASTM F3125/F3125M bolts, including Grades A325/F1852 and A490/F2280 high-strength bolts used in bearing-type and slip-critical connections. It’s important to note that the provided bolt lengths may not automatically exclude bolt threads from the shear plane(s).

| Grip Inches | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1/2 | 5/8 | 3/4 | 7/8 | 1 | 1 1/8 | 1 1/4 | 1 3/8 | 1 1/2 | |

| 3/4 | 1 1/2 | 1 3/4 | *** | 2 | *** | *** | 2 1/2 | *** | 2 3/4 |

| 13/16 | 1 1/2 | 1 3/4 | 2 | 2 | 2 1/4 | 2 1/2 | 2 1/2 | 2 3/4 | 2 3/4 |

| 7/8 | 1 3/4 | 1 3/4 | 2 | 2 | 2 1/4 | 2 1/2 | 2 1/2 | 2 3/4 | 2 3/4 |

| 15/16 | 1 3/4 | 2 | 2 | 2 1/4 | 2 1/4 | 2 1/2 | 2 3/4 | 2 3/4 | 3 |

| 1 | 1 3/4 | 2 | 2 | 2 1/4 | 2 1/4 | 2 1/2 | 2 3/4 | 2 3/4 | 3 |

| 1 1/16 | 1 3/4 | 2 | 2 1/4 | 2 1/4 | 2 1/2 | 2 3/4 | 2 3/4 | 3 | 3 |

| 1 1/8 | 2 | 2 | 2 1/4 | 2 1/4 | 2 1/2 | 2 3/4 | 2 3/4 | 3 | 3 |

| 1 3/16 | 2 | 2 1/4 | 2 1/4 | 2 1/2 | 2 1/2 | 2 3/4 | 3 | 3 | 3 1/4 |

| 1 1/4 | 2 | 2 1/4 | 2 1/4 | 2 1/2 | 2 1/2 | 2 3/4 | 3 | 3 | 3 1/4 |

| 1 5/16 | 2 | 2 1/4 | 2 1/2 | 2 1/2 | 2 3/4 | 3 | 3 | 3 1/4 | 3 1/4 |

| 1 3/8 | 2 1/4 | 2 1/4 | 2 1/2 | 2 1/2 | 2 3/4 | 3 | 3 | 3 1/4 | 3 1/4 |

| 1 7/16 | 2 1/4 | 2 1/2 | 2 1/2 | 2 3/4 | 2 3/4 | 3 | 3 1/4 | 3 1/4 | 3 1/2 |

| 1 1/2 | 2 1/4 | 2 1/2 | 2 1/2 | 2 3/4 | 2 3/4 | 3 | 3 1/4 | 3 1/4 | 3 1/2 |

| 1 9/16 | 2 1/4 | 2 1/2 | 2 3/4 | 3 3/4 | 3 | 3 1/4 | 3 1/4 | 3 1/2 | 3 1/2 |

| 1 5/8 | 2 1/2 | 2 1/2 | 2 3/4 | 2 3/4 | 3 | 3 1/4 | 3 1/4 | 3 1/2 | 3 1/2 |

| 1 11/16 | 2 1/2 | 2 3/4 | 2 3/4 | 3 | 3 | 3 1/4 | 3 1/2 | 3 1/2 | 3 3/4 |

| 1 3/4 | 2 1/2 | 2 3/4 | 2 3/4 | 3 | 3 | 3 1/4 | 3 1/2 | 3 1/2 | 3 3/4 |

| 1 13/16 | 2 1/2 | 2 3/4 | 3 | 3 | 3 1/4 | 3 1/2 | 3 1/2 | 3 3/4 | 3 3/4 |

| 1 7/8 | 2 3/4 | 2 3/4 | 3 | 3 | 3 1/4 | 3 1/2 | 3 1/2 | 3 3/4 | 3 3/4 |

| 1 15/16 | 2 3/4 | 3 | 3 | 3 1/4 | 3 1/4 | 3 1/2 | 3 3/4 | 3 3/4 | 4 |

| 2 | 2 3/4 | 3 | 3 | 3 1/4 | 3 1/4 | 3 1/2 | 3 3/4 | 3 3/4 | 4 |

| 2 1/16 | 2 3/4 | 3 | 3 1/4 | 3 1/4 | 3 1/2 | 3 3/4 | 3 3/4 | 4 | 4 |

| 2 1/8 | 3 | 3 | 3 1/4 | 3 1/4 | 3 1/2 | 3 3/4 | 3 3/4 | 4 | 4 |

| 2 3/16 | 3 | 3 1/4 | 3 1/4 | 3 1/2 | 3 1/2 | 3 3/4 | 4 | 4 | 4 1/4 |

| 2 1/4 | 3 | 3 1/4 | 3 1/4 | 3 1/2 | 3 1/2 | 3 3/4 | 4 | 4 | 4 1/4 |

| 2 5/16 | 3 | 3 1/4 | 3 1/2 | 3 1/2 | 3 3/4 | 4 | 4 | 4 1/4 | 4 1/4 |

| 2 3/8 | 3 1/4 | 3 1/4 | 3 1/2 | 3 1/2 | 3 3/4 | 4 | 4 | 4 1/4 | 4 1/4 |

| 2 7/16 | 3 1/4 | 3 1/2 | 3 1/2 | 3 3/4 | 3 3/4 | 4 | 4 1/4 | 4 1/4 | 4 1/2 |

| 2 1/2 | 3 1/4 | 3 1/2 | 3 1/2 | 3 3/4 | 3 3/4 | 4 | 4 1/4 | 4 1/4 | 4 1/2 |

| 2 9/16 | 3 1/4 | 3 1/2 | 3 3/4 | 3 3/4 | 4 | 4 1/4 | 4 1/4 | 4 1/2 | 4 1/2 |

| 2 5/8 | 3 1/2 | 3 1/2 | 3 3/4 | 3 3/4 | 4 | 4 1/4 | 41/4 | 4 1/2 | 4 1/2 |

| 2 11/16 | 3 1/2 | 3 3/4 | 3 3/4 | 4 | 4 | 4 1/4 | 4 1/2 | 4 1/2 | 4 3/4 |

| 2 3/4 | 3 1/2 | 3 3/4 | 3 3/4 | 4 | 4 | 4 1/4 | 4 1/2 | 4 1/2 | 4 3/4 |

| 2 13/16 | 3 1/2 | 3 3/4 | 4 | 4 | 4 1/4 | 4 1/2 | 4 1/2 | 4 3/4 | 4 3/4 |

| 2 7/8 | 3 3/4 | 3 3/4 | 4 | 4 | 4 1/4 | 4 1/2 | 4 1/2 | 4 3/4 | 4 3/4 |

| 2 15/16 | 3 3/4 | 4 | 4 | 4 1/4 | 4 1/4 | 4 1/2 | 4 3/4 | 4 3/4 | 5 |

| 3 | 3 3/4 | 4 | 4 | 4 1/4 | 4 1/4 | 4 1/2 | 4 3/4 | 4 3/4 | 5 |

| 3 1/16 | 3 3/4 | 4 | 4 1/4 | 4 1/4 | 4 1/2 | 4 3/4 | 4 3/4 | 5 | 5 |

| 3 1/8 | 4 | 4 | 4 1/4 | 4 1/4 | 4 1/2 | 4 3/4 | 4 3/4 | 5 | 5 |

| 3 3/16 | 4 | 4 1/4 | 4 1/4 | 4 1/2 | 4 1/2 | 4 3/4 | 5 | 5 | 5 1/4 |

| 3 1/4 | 4 | 4 1/4 | 4 1/4 | 4 1/2 | 4 1/2 | 4 3/4 | 5 | 5 | 5 1/4 |

| 3 5/16 | 4 | 4 1/4 | 4 1/2 | 4 1/2 | 4 3/4 | 5 | 5 | 5 1/4 | 5 1/4 |

| 3 3/8 | 4 1/4 | 4 1/4 | 4 1/2 | 4 1/2 | 4 3/4 | 5 | 5 | 5 1/4 | 5 1/4 |

| 3 7/16 | 4 1/4 | 4 1/2 | 4 1/2 | 4 3/4 | 4 3/4 | 5 | 5 1/4 | 5 1/4 | 5 1/2 |

| 3 1/2 | 4 1/4 | 4 1/2 | 4 1/2 | 4 3/4 | 4 3/4 | 5 | 5 1/4 | 5 1/4 | 5 1/2 |

| 3 9/16 | 4 1/4 | 4 1/2 | 4 3/4 | 4 3/4 | 5 | 5 1/4 | 5 1/4 | 5 1/2 | 5 1/2 |

| 3 5/8 | 4 1/2 | 4 1/2 | 4 3/4 | 4 3/4 | 5 | 5 1/4 | 5 1/4 | 5 1/2 | 5 1/2 |

| 3 11/16 | 4 1/2 | 4 3/4 | 4 3/4 | 5 | 5 | 5 1/4 | 5 1/2 | 5 1/2 | 5 3/4 |

| 3 3/4 | 4 1/2 | 4 3/4 | 4 3/4 | 5 | 5 | 5 1/4 | 5 1/2 | 5 1/2 | 5 3/4 |

| 3 13/16 | 4 1/2 | 4 3/4 | 5 | 5 | 5 1/4 | 5 1/2 | 5 1/2 | 5 3/4 | 5 3/4 |

| 3 7/8 | 4 3/4 | 4 3/4 | 5 | 5 | 5 1/4 | 5 1/2 | 5 1/2 | 5 3/4 | 5 3/4 |

| 3 15/16 | 4 3/4 | 5 | 5 | 5 1/4 | 5 1/4 | 5 1/2 | 5 3/4 | 5 3/4 | 6 |

| 4 | 4 3/4 | 5 | 5 | 5 1/4 | 5 1/2 | 5 1/2 | 5 3/4 | 5 3/4 | 6 |

| 4 1/16 | 4 3/4 | 5 | 5 1/4 | 5 1/4 | 5 1/2 | 5 3/4 | 5 3/4 | 6 | 6 |

| Bolt Diam. | ||||||

|---|---|---|---|---|---|---|

| Body Diam. | Head Diam. | Height | Thread Length | Width Across Spline | ||

| Max | Max | Max | Min | Basic | Basic | |

| 5/8-11 | 0.642 | 1.313 | 0.403 | 0.378 | 1.25 | 0.43 |

| 3/4-10 | 0.768 | 1.58 | 0.483 | 0.455 | 1.38 | 0.53 |

| 7/8-9 | 0.895 | 1.88 | 0.563 | 0.531 | 1.5 | 0.61 |

| 1-8 | 1.022 | 2.158 | 0.627 | 0.591 | 1.75 | 0.7 |

| 1 1/8-7 | 1.149 | 2.375 | 0.718 | 0.658 | 2 | 0.8 |

| 1 1/4-7 | 1.277 | 2.76 | 0.813 | 0.749 | 2 | 0.4 |

| 1 3/8-6 | 1.404 | 2.91 | 0.878 | 0.81 | 2.25 | 1 |

| 1 1/2-6 | 1.531 | 3.16 | 0.974 | 0.902 | 2.25 | 1.1 |

| F3125 Grade F2280 Dimensions, Threads & Grade Marking | ||

|---|---|---|

| Type 1 | Type 3 | |

| Style – Twist-Off Bolts | ||

| Dimensions, ASMEB | B18.2.6 | B18.2.6 |

| Thread Fit, ASMEB | B1.1 UNC 2A | B1.1 UNC 2A |

| Grade MarkingA, D | A490TC | A490TC |

| Grade Alt. MarkingA, C | A490 | A490 |

| F3125 Gr.A325 & F1852 Matching Components | ||

|---|---|---|

| Type 1 | Type 3 | |

| Recommended Nut and Washer | ||

| Plain Nut | A563 DH | A563 DH3 |

| Suitable AlternativeE | DH3, D, C, C3 | C3 |

| Coated Nut | A563 DH | A563 DH3 |

| Flat, Bevel or Thick washer if used | F436-1 | F436-3 |

| 120 ksi Bolt AssembliesA | |||

|---|---|---|---|

| Commonly Applied Coatings | Grade or Class | ||

| F2329 | Hot Dip Galvanized / 50 μm | ||

| B695 | Class 55 | ||

| Other Coatings | Classification codes | ||

| Corrosion | Appearance | Coefficient of friction | |

| F3393 | D | 1 | RB |

*Note that Boulons Plus offer Gr.F1852 only in plain and Mech. Galv as per ASTM B695 Class 55

Features | F3125 KPF | F3125 Domestic |

|---|---|---|

Keg Material | Metal | Metal |

Keg Max Weight | 65 Lbs | 235 Lbs |

Come With Handle | ✔ | X |

Quickly Open/Seal Lid | ✔ | X |

Kegs Per Skid | 27 | 9 |

Keg Height | 8 1/4 inches | 20 inches |

Keg Visual |  |  |

| DIAM: 5/8 | ||||

|---|---|---|---|---|

| LENGTH | BOLTS/KEG | LBS/KEG | BOLTS/KEG | LBS/KEG |

| 1 1/2 | 150 | 57 | 500 | 204 |

| 1 3/4 | 140 | 57 | 470 | 206 |

| 2 | 140 | 60 | 450 | 206 |

| 2 1/4 | 130 | 57 | 410 | 196 |

| 2 1/2 | 120 | 56 | 380 | 190 |

| 2 3/4 | 110 | 54 | 350 | 182 |

| 3 | N/A | N/A | 325 | 176 |

| DIAM: 3/4 | ||||

|---|---|---|---|---|

| LENGTH | BOLTS/KEG | LBS/KEG | BOLTS/KEG | LBS/KEG |

| 1 3/4 | 95 | 59 | 300 | 205 |

| 2 | 90 | 59 | 280 | 200 |

| 2 1/4 | 85 | 58 | 270 | 200 |

| 2 1/2 | 80 | 57 | 250 | 194 |

| 2 3/4 | 80 | 59 | 250 | 201 |

| 3 | 75 | 58 | 240 | 203 |

| 3 1/4 | 75 | 60 | 230 | 202 |

| 3 1/2 | 70 | 58 | 220 | 200 |

| 3 3/4 | 70 | 60 | 200 | 188 |

| 4 | 70 | 63 | 190 | 184 |

| 4 1/2 | 60 | 57 | 180 | 187 |

| 4 3/4 | 60 | 59 | 160 | 172 |

| 5 | 60 | 61 | 150 | 166 |

| 5 1/2 | 50 | 53 | 140 | 163 |

| 6 | 50 | 57 | 130 | 161 |

| DIAM: 7/8 | ||||

|---|---|---|---|---|

| LENGTH | BOLTS/KEG | LBS/KEG | BOLTS/KEG | LBS/KEG |

| 2 | 60 | 57 | 200 | 206 |

| 2 1/4 | 60 | 59 | 190 | 203 |

| 2 1/2 | 55 | 57 | 180 | 202 |

| 2 3/4 | 55 | 59 | 180 | 209 |

| 3 | 50 | 56 | 170 | 204 |

| 3 1/4 | 50 | 58 | 160 | 201 |

| 3 1/2 | 50 | 60 | 150 | 194 |

| 3 3/4 | 45 | 56 | 140 | 187 |

| 4 | 45 | 58 | 140 | 194 |

| 4 1/4 | 40 | 54 | 130 | 186 |

| 4 1/2 | 40 | 54 | 120 | 177 |

| 4 3/4 | 30 | 42 | 120 | 183 |

| 5 | 30 | 43 | 115 | 180 |

| 5 1/2 | 30 | 47 | 100 | 166 |

| 6 | 30 | 49 | 95 | 166 |

| DIAM: 1 | ||||

|---|---|---|---|---|

| LENGTH | BOLTS/KEG | LBS/KEG | BOLTS/KEG | LBS/KEG |

| 2 | 45 | 59 | 150 | 214 |

| 2 1/4 | 45 | 61 | 140 | 204 |

| 2 1/2 | 40 | 56 | 130 | 197 |

| 2 3/4 | 40 | 58 | 130 | 204 |

| 3 | 40 | 60 | 120 | 196 |

| 3 1/4 | 35 | 55 | 120 | 203 |

| 3 1/2 | 35 | 57 | 110 | 192 |

| 3 3/4 | 35 | 58 | 110 | 198 |

| 4 | 35 | 60 | 100 | 187 |

| 4 1/4 | 30 | 54 | 90 | 173 |

| 4 1/2 | 30 | 55 | 90 | 178 |

| 4 3/4 | 30 | 57 | 90 | 183 |

| 5 | 30 | 58 | 85 | 178 |

| 5 1/2 | 25 | 51 | 80 | 177 |

| 6 | 25 | 54 | 70 | 163 |

| 6 1/2 | 25 | 57 | 65 | 156 |

| 7 | 20 | 48 | 60 | 145 |

| 7 1/2 | 20 | 50 | 55 | 135 |

| 8 | 20 | 53 | 55 | 135 |

| 8 1/2 | N/A | N/A | 50 | 123 |

| DIAM: 1 1/8 | ||||

|---|---|---|---|---|

| LENGTH | BOLTS/KEG | LBS/KEG | BOLTS/KEG | LBS/KEG |

| 2 3/4 | 30 | 58 | 80 | 184 |

| 3 | 30 | 61 | 80 | 189 |

| 3 1/4 | 30 | 63 | 70 | 172 |

| 3 1/2 | 25 | 54 | 70 | 175 |

| 3 3/4 | 25 | 56 | 70 | 183 |

| 4 | 25 | 57 | 70 | 186 |

| 4 1/4 | 25 | 59 | 60 | 165 |

| 4 1/2 | 25 | 61 | 60 | 168 |

| 4 3/4 | 20 | 50 | 50 | 146 |

| 5 | 20 | 51 | 50 | 148 |

| 5 1/2 | 20 | 54 | 50 | 155 |

| 6 | 20 | 57 | 50 | 162 |

| 6 1/2 | 20 | 59 | 50 | 169 |

| 7 | 15 | 47 | 40 | 141 |

| 7 1/2 | 15 | 49 | 40 | 147 |

| 8 | 15 | 51 | 40 | 147 |

| 8 1/2 | N/A | N/A | 35 | 134 |

| DIAM: 1 1/4 | ||||

|---|---|---|---|---|

| LENGTH | BOLTS/KEG | LBS/KEG | BOLTS/KEG | LBS/KEG |

| 3 | N/A | N/A | 80 | 219 |

| 3 1/4 | N/A | N/A | 80 | 226 |

| 3 1/2 | N/A | N/A | 80 | 233 |

| 3 3/4 | N/A | N/A | 70 | 210 |

| 4 | N/A | N/A | 70 | 217 |

| 4 1/4 | N/A | N/A | 70 | 222 |

| 4 1/2 | N/A | N/A | 60 | 196 |

| 4 3/4 | N/A | N/A | 60 | 201 |

| 5 | N/A | N/A | 50 | 173 |

| 5 1/2 | N/A | N/A | 50 | 181 |

| 6 | N/A | N/A | 50 | 190 |

| 6 1/2 | N/A | N/A | 50 | 199 |

| 7 | N/A | N/A | 45 | 187 |

| 7 1/2 | N/A | N/A | 40 | 173 |

| 8 | N/A | N/A | 40 | 180 |

| 8 1/2 | N/A | N/A | 40 | 187 |

| 9 | N/A | N/A | 35 | 170 |

| 9 1/2 | N/A | N/A | 30 | 152 |

As per Section 16 of ASTM F3125/F3125-23, here’s a summary of the requirements for packaging and package marking of heavy hex bolts and twist-off bolt assemblies.

16. Packaging and Package Marking:

16.1 Packaging:

16.2 Package Marking:

| Gr.A325 & Gr.F1852 Chemical Requirements | ||||

|---|---|---|---|---|

| Heat Analysis | Type 1 | Type 3 | ||

| Carbon or Alloy Steel With Or Without Boron | Composition A | Composition B | Based On Corrosion IndexB | |

| Carbon | 0.30 – 0.52 | 0.33 – 0.40 | 038 – 0.48 | 0.30 – 0.52 max |

| Manganese | 0.60 min | 0.90 – 1.20 | 0.70 – 0.90 | 0.60 min |

| Phosphorus, max | 0.035 | 0.035 | 0.035 | 0.035 |

| Sulfur, max | 0.04 | 0.04 | 0.04 | 0.04 |

| Silicon | 0.15 – 0.30 | 0.15 – 0.30 | 0.30 – 0.50 | D |

| Boron | 0.003 max | D | D | D |

| Copper | D | 0.25 – 0.45 | 0.20 – 0.40 | 0.20 – 0.60 |

| Nickel | D | 0.25 – 0.45 | 0.50 – 0.80 | 0.20E min |

| Chromium | D | 0.45 – 0.65 | 0.50 – 0.75 | 0.45 min |

| Vanadium | D | D | D | D |

| Molybdenum | D | D | 0.06 max | 0.10E min |

| Titanium | D | D | D | D |

| Gr.A325 & Gr.F1852 Mechanical Properties (Full Size Bolts) | ||||

|---|---|---|---|---|

| Diam. | Stress AreaA | Tensile min | Proof Load Length Measurement min | Alternative Proof Load Yield Strength Method min |

| In. | In2 | lbf | lbf | lbf |

| 1/2-13 UNC | 0.142 | 17,050 | 12,050 | 13,050 |

| 5/8-11 UNC | 0.226 | 27,100 | 19,200 | 20,800 |

| 3/4-10 UNC | 0.334 | 40,100 | 28,400 | 30,700 |

| 7/8-9 UNC | 0.462 | 55,450 | 39,250 | 42,500 |

| 1-8 UNC | 0.606 | 72,700 | 51,500 | 55,750 |

| 1 1/8-7 UNC | 0.763 | 91,600B | 64,900B | 70,250B |

| 1 1/4-7 UNC | 0.969 | 116,300B | 82,400B | 89,200B |

| 1 3/8-6 UNC | 1.155 | 138,600B | 98,200B | 106,300B |

| 1 1/2-6 UNC | 1.405 | 168,600B | 119,500B | 129,300B |

| Above values based on | – | 120 Ksi | 85 Ksi | 92 Ksi |

| Gr.A325 & Gr.F1852 Mechanical Properties (Specimen Machined Bolts) | ||||

|---|---|---|---|---|

| Tensile min. | Tensile max. | Yield min. | Elongation in 4D min % | Reduction of Area min % |

| 120 ksi | … | 92 ksi | 14 | 35 |

| Gr.A325 & F1852 Hardness Requirements for bolts | |||

|---|---|---|---|

| Brinell HB | Rockwell HRC | ||

| Min | Max | Min | Max |

| 253 | 319 | 25 | 34 |

| Gr. A325 & Gr.F1852 Pre-tension Requirements by Strength and Diameter | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Bolt Diam. | 1/2 | 5/8 | 3/4 | 7/8 | 1 | 1 1/8 | 1 1/4 | 1 3/8 | 1 1/2 |

| Kip | 1 | 2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 |

| lbf | 1,000 | 2,000 | 3,000 | 4,000 | 5,000 | 6,000 | 8,000 | 10,000 | 12,000 |

| Gr. F1852 Assembly Min. Installation Tension | |||||||

|---|---|---|---|---|---|---|---|

| Bolt Diam. | 1/2 | 5/8 | 3/4 | 7/8 | 1 | 1 1/8 | 1 1/4 |

| lbf | 12,550 | 19,900 | 29,450 | 40,750 | 53,450 | 67,350 | 85,500 |

| LOT SIZE | |||

|---|---|---|---|

| 1-50 | 1 | ||

| 51-280 | 2 | ||

| 281-3,200 | 3 | ||

| 3,201-35,000 | 4 | ||

| 35,001-150,000 | 5 | ||

| 150,001-500,000 | 6 | ||

| 500,001+ | 7 |

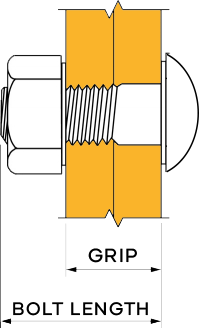

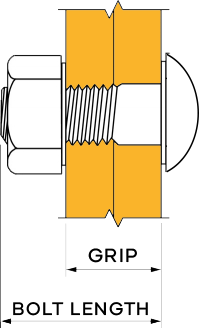

ASTM F3125 Grade A490 fasteners are engineered for heavy-duty structural applications, offering unmatched tensile strength of 150 ksi. These bolts excel in high-stress environments, making them ideal for critical connections in infrastructure projects like bridges and high-rise buildings. Installation requires calibrated torque wrenches to achieve precise tension, ensuring the A490 grade’s exceptional load-bearing capabilities. When reliability and strength are paramount, ASTM F3125 Grade A490 fasteners deliver superior performance in challenging construction scenarios.

*For Weather resistance, see Type 3 products

** Please take note that Boulons Plus only sell pre-assembled sets including 1 bolt, 1 washer and 1 nut.

Facilitating the selection of bolt length for a specific grip and bolt diameter is simplified by referring to the “Bolt Lengths for Various Grips” chart on page 6-167 in the Handbook of Steel Construction, 11th edition. This chart is relevant to the Imperial Series of ASTM F3125/F3125M bolts, including Grades A325/F1852 and A490/F2280 high-strength bolts used in bearing-type and slip-critical connections. It’s important to note that the provided bolt lengths may not automatically exclude bolt threads from the shear plane(s).

| Grip Inches | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1/2 | 5/8 | 3/4 | 7/8 | 1 | 1 1/8 | 1 1/4 | 1 3/8 | 1 1/2 | |

| 3/4 | 1 1/2 | 1 3/4 | *** | 2 | *** | *** | 2 1/2 | *** | 2 3/4 |

| 13/16 | 1 1/2 | 1 3/4 | 2 | 2 | 2 1/4 | 2 1/2 | 2 1/2 | 2 3/4 | 2 3/4 |

| 7/8 | 1 3/4 | 1 3/4 | 2 | 2 | 2 1/4 | 2 1/2 | 2 1/2 | 2 3/4 | 2 3/4 |

| 15/16 | 1 3/4 | 2 | 2 | 2 1/4 | 2 1/4 | 2 1/2 | 2 3/4 | 2 3/4 | 3 |

| 1 | 1 3/4 | 2 | 2 | 2 1/4 | 2 1/4 | 2 1/2 | 2 3/4 | 2 3/4 | 3 |

| 1 1/16 | 1 3/4 | 2 | 2 1/4 | 2 1/4 | 2 1/2 | 2 3/4 | 2 3/4 | 3 | 3 |

| 1 1/8 | 2 | 2 | 2 1/4 | 2 1/4 | 2 1/2 | 2 3/4 | 2 3/4 | 3 | 3 |

| 1 3/16 | 2 | 2 1/4 | 2 1/4 | 2 1/2 | 2 1/2 | 2 3/4 | 3 | 3 | 3 1/4 |

| 1 1/4 | 2 | 2 1/4 | 2 1/4 | 2 1/2 | 2 1/2 | 2 3/4 | 3 | 3 | 3 1/4 |

| 1 5/16 | 2 | 2 1/4 | 2 1/2 | 2 1/2 | 2 3/4 | 3 | 3 | 3 1/4 | 3 1/4 |

| 1 3/8 | 2 1/4 | 2 1/4 | 2 1/2 | 2 1/2 | 2 3/4 | 3 | 3 | 3 1/4 | 3 1/4 |

| 1 7/16 | 2 1/4 | 2 1/2 | 2 1/2 | 2 3/4 | 2 3/4 | 3 | 3 1/4 | 3 1/4 | 3 1/2 |

| 1 1/2 | 2 1/4 | 2 1/2 | 2 1/2 | 2 3/4 | 2 3/4 | 3 | 3 1/4 | 3 1/4 | 3 1/2 |

| 1 9/16 | 2 1/4 | 2 1/2 | 2 3/4 | 3 3/4 | 3 | 3 1/4 | 3 1/4 | 3 1/2 | 3 1/2 |

| 1 5/8 | 2 1/2 | 2 1/2 | 2 3/4 | 2 3/4 | 3 | 3 1/4 | 3 1/4 | 3 1/2 | 3 1/2 |

| 1 11/16 | 2 1/2 | 2 3/4 | 2 3/4 | 3 | 3 | 3 1/4 | 3 1/2 | 3 1/2 | 3 3/4 |

| 1 3/4 | 2 1/2 | 2 3/4 | 2 3/4 | 3 | 3 | 3 1/4 | 3 1/2 | 3 1/2 | 3 3/4 |

| 1 13/16 | 2 1/2 | 2 3/4 | 3 | 3 | 3 1/4 | 3 1/2 | 3 1/2 | 3 3/4 | 3 3/4 |

| 1 7/8 | 2 3/4 | 2 3/4 | 3 | 3 | 3 1/4 | 3 1/2 | 3 1/2 | 3 3/4 | 3 3/4 |

| 1 15/16 | 2 3/4 | 3 | 3 | 3 1/4 | 3 1/4 | 3 1/2 | 3 3/4 | 3 3/4 | 4 |

| 2 | 2 3/4 | 3 | 3 | 3 1/4 | 3 1/4 | 3 1/2 | 3 3/4 | 3 3/4 | 4 |

| 2 1/16 | 2 3/4 | 3 | 3 1/4 | 3 1/4 | 3 1/2 | 3 3/4 | 3 3/4 | 4 | 4 |

| 2 1/8 | 3 | 3 | 3 1/4 | 3 1/4 | 3 1/2 | 3 3/4 | 3 3/4 | 4 | 4 |

| 2 3/16 | 3 | 3 1/4 | 3 1/4 | 3 1/2 | 3 1/2 | 3 3/4 | 4 | 4 | 4 1/4 |

| 2 1/4 | 3 | 3 1/4 | 3 1/4 | 3 1/2 | 3 1/2 | 3 3/4 | 4 | 4 | 4 1/4 |

| 2 5/16 | 3 | 3 1/4 | 3 1/2 | 3 1/2 | 3 3/4 | 4 | 4 | 4 1/4 | 4 1/4 |

| 2 3/8 | 3 1/4 | 3 1/4 | 3 1/2 | 3 1/2 | 3 3/4 | 4 | 4 | 4 1/4 | 4 1/4 |

| 2 7/16 | 3 1/4 | 3 1/2 | 3 1/2 | 3 3/4 | 3 3/4 | 4 | 4 1/4 | 4 1/4 | 4 1/2 |

| 2 1/2 | 3 1/4 | 3 1/2 | 3 1/2 | 3 3/4 | 3 3/4 | 4 | 4 1/4 | 4 1/4 | 4 1/2 |

| 2 9/16 | 3 1/4 | 3 1/2 | 3 3/4 | 3 3/4 | 4 | 4 1/4 | 4 1/4 | 4 1/2 | 4 1/2 |

| 2 5/8 | 3 1/2 | 3 1/2 | 3 3/4 | 3 3/4 | 4 | 4 1/4 | 41/4 | 4 1/2 | 4 1/2 |

| 2 11/16 | 3 1/2 | 3 3/4 | 3 3/4 | 4 | 4 | 4 1/4 | 4 1/2 | 4 1/2 | 4 3/4 |

| 2 3/4 | 3 1/2 | 3 3/4 | 3 3/4 | 4 | 4 | 4 1/4 | 4 1/2 | 4 1/2 | 4 3/4 |

| 2 13/16 | 3 1/2 | 3 3/4 | 4 | 4 | 4 1/4 | 4 1/2 | 4 1/2 | 4 3/4 | 4 3/4 |

| 2 7/8 | 3 3/4 | 3 3/4 | 4 | 4 | 4 1/4 | 4 1/2 | 4 1/2 | 4 3/4 | 4 3/4 |

| 2 15/16 | 3 3/4 | 4 | 4 | 4 1/4 | 4 1/4 | 4 1/2 | 4 3/4 | 4 3/4 | 5 |

| 3 | 3 3/4 | 4 | 4 | 4 1/4 | 4 1/4 | 4 1/2 | 4 3/4 | 4 3/4 | 5 |

| 3 1/16 | 3 3/4 | 4 | 4 1/4 | 4 1/4 | 4 1/2 | 4 3/4 | 4 3/4 | 5 | 5 |

| 3 1/8 | 4 | 4 | 4 1/4 | 4 1/4 | 4 1/2 | 4 3/4 | 4 3/4 | 5 | 5 |

| 3 3/16 | 4 | 4 1/4 | 4 1/4 | 4 1/2 | 4 1/2 | 4 3/4 | 5 | 5 | 5 1/4 |

| 3 1/4 | 4 | 4 1/4 | 4 1/4 | 4 1/2 | 4 1/2 | 4 3/4 | 5 | 5 | 5 1/4 |

| 3 5/16 | 4 | 4 1/4 | 4 1/2 | 4 1/2 | 4 3/4 | 5 | 5 | 5 1/4 | 5 1/4 |

| 3 3/8 | 4 1/4 | 4 1/4 | 4 1/2 | 4 1/2 | 4 3/4 | 5 | 5 | 5 1/4 | 5 1/4 |

| 3 7/16 | 4 1/4 | 4 1/2 | 4 1/2 | 4 3/4 | 4 3/4 | 5 | 5 1/4 | 5 1/4 | 5 1/2 |

| 3 1/2 | 4 1/4 | 4 1/2 | 4 1/2 | 4 3/4 | 4 3/4 | 5 | 5 1/4 | 5 1/4 | 5 1/2 |

| 3 9/16 | 4 1/4 | 4 1/2 | 4 3/4 | 4 3/4 | 5 | 5 1/4 | 5 1/4 | 5 1/2 | 5 1/2 |

| 3 5/8 | 4 1/2 | 4 1/2 | 4 3/4 | 4 3/4 | 5 | 5 1/4 | 5 1/4 | 5 1/2 | 5 1/2 |

| 3 11/16 | 4 1/2 | 4 3/4 | 4 3/4 | 5 | 5 | 5 1/4 | 5 1/2 | 5 1/2 | 5 3/4 |

| 3 3/4 | 4 1/2 | 4 3/4 | 4 3/4 | 5 | 5 | 5 1/4 | 5 1/2 | 5 1/2 | 5 3/4 |

| 3 13/16 | 4 1/2 | 4 3/4 | 5 | 5 | 5 1/4 | 5 1/2 | 5 1/2 | 5 3/4 | 5 3/4 |

| 3 7/8 | 4 3/4 | 4 3/4 | 5 | 5 | 5 1/4 | 5 1/2 | 5 1/2 | 5 3/4 | 5 3/4 |

| 3 15/16 | 4 3/4 | 5 | 5 | 5 1/4 | 5 1/4 | 5 1/2 | 5 3/4 | 5 3/4 | 6 |

| 4 | 4 3/4 | 5 | 5 | 5 1/4 | 5 1/2 | 5 1/2 | 5 3/4 | 5 3/4 | 6 |

| 4 1/16 | 4 3/4 | 5 | 5 1/4 | 5 1/4 | 5 1/2 | 5 3/4 | 5 3/4 | 6 | 6 |

| Bolt Diam. | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Body Diam. | Width Across Flat | Width Across Corners | Head Height | Thread Length | ||||||

| Max | Basic | Max | Min | Max | Min | Basic | Max | Min | Basic | |

| 1/2-13 | 0.515 | 7/8 | 0.875 | 0.850 | 1.010 | 0.969 | 5/16 | 0.323 | 0.302 | 1.00 |

| 5/8-11 | 0.642 | 1 1/16 | 1.062 | 1.031 | 1.227 | 1.175 | 25/64 | 0.403 | 0.378 | 1.25 |

| 3/4-10 | 0.768 | 1 1/4 | 1.250 | 1.212 | 1.443 | 1.383 | 15/32 | 0.483 | 0.455 | 1.38 |

| 7/8-9 | 0.895 | 1 7/16 | 1.438 | 1.394 | 1.660 | 1.589 | 35/64 | 0.563 | 0.531 | 1.50 |

| 1-8 | 1.022 | 1 5/8 | 1.625 | 1.575 | 1.876 | 1.796 | 39/64 | 0.627 | 0.591 | 1.75 |

| 1 1/8-7 | 1.149 | 1 13/16 | 1.812 | 1.756 | 2.093 | 2.002 | 11/16 | 0.718 | 0.658 | 2.00 |

| 1 1/4-7 | 1.277 | 2 | 2.00 | 1.938 | 2.309 | 2.209 | 25/32 | 0.813 | 0.749 | 2.00 |

| 1 3/8-6 | 1.404 | 2 3/16 | 2.188 | 2.119 | 2.526 | 2.416 | 27/32 | 0.878 | 0.810 | 2.25 |

| 1 1/2-6 | 1.531 | 2 3/8 | 2.375 | 2.300 | 2.742 | 2.622 | 15/16 | 0.974 | 0.902 | 2.25 |

| F3125 Grade A490 Dimensions, Threads & Grade Marking | ||

|---|---|---|

| Type 1 | Type 3 | |

| Style – Heavy Hex Bolts | ||

| Dimensions, ASMEB | B18.2.6 | B18.2.6 |

| Thread Fit, ASMEB | B1.1 UNC 2A | B1.1 UNC 2A |

| Grade MarkingD | A490 | A490 |

| F3125 Gr.A490 & F2280 Matching Components | ||

|---|---|---|

| Type 1 | Type 3 | |

| Recommended Nut and Washer | ||

| Plain Nut | A563 DH | A563 DH3 |

| Suitable AlternativeE | – | – |

| Coated Nut | A563 DH | A563 DH3 |

| Flat, Bevel or Thick washer if used | F436-1 | F436-3 |

| 150 ksi Bolt AssembliesA | |||

|---|---|---|---|

| Qualified Coatings | Classification codes | ||

| Corrosion | Appearance | Coefficient of friction | |

| F3393 | D | 1 | RB |

Features | F3125 KPF | F3125 Domestic |

|---|---|---|

Keg Material | Metal | Plastic |

Keg Max Weight | 65 Lbs | 95 Lbs |

Come With Handle | ✔ | ✔ |

Quickly Open/Seal Lid | ✔ | ✔ |

Kegs Per Skid | 27 | 18 |

Keg Height | 8 1/4 inches | 11 inches |

Keg Visual |  |  |

| DIAM: 1/2 | ||||

|---|---|---|---|---|

| LENGTH | BOLTS/KEG | Lbs/KEG | BOLTS/KEG | Lbs/KEG |

| 1 1/4 | 270 | 59 | 450 | 92 |

| 1 1/2 | 250 | 115 | 400 | 80 |

| 1 3/4 | 240 | 115 | 350 | 81 |

| 2 | 240 | 125 | 350 | 86 |

| 2 1/4 | 230 | 62 | 325 | 85 |

| 2 1/2 | 220 | 62 | 300 | 83 |

| 2 3/4 | 210 | 63 | 275 | 80 |

| 3 | 200 | 62 | 265 | 81 |

| 3 1/4 | 190 | 62 | 250 | 80 |

| 3 1/2 | 180 | 61 | 240 | 80 |

| 3 3/4 | 170 | 60 | 215 | 75 |

| 4 | 160 | 59 | 200 | 73 |

| 4 1/4 | N/A | N/A | 200 | 75 |

| 4 1/2 | N/A | N/A | 190 | 74 |

| 4 3/4 | N/A | N/A | 175 | 71 |

| 5 | N/A | N/A | 150 | 63 |

| DIAM: 5/8 | ||||

|---|---|---|---|---|

| LENGTH | BOLTS/KEG | LBS/KEG | BOLTS/KEG | LBS/KEG |

| 1 1/2 | 150 | 56 | 250 | 94 |

| 1 3/4 | 140 | 55 | 250 | 100 |

| 2 | 140 | 58 | 225 | 95 |

| 2 1/4 | 130 | 57 | 200 | 89 |

| 2 1/2 | 130 | 60 | 200 | 93 |

| 2 3/4 | 120 | 58 | 175 | 85 |

| 3 | 120 | 60 | 165 | 84 |

| 3 1/4 | 110 | 58 | 150 | 80 |

| 3 1/2 | 110 | 60 | 150 | 83 |

| 3 3/4 | 100 | 57 | 130 | 75 |

| 4 | 100 | 59 | 130 | 78 |

| 4 1/4 | 90 | 55 | 120 | 75 |

| 4 1/2 | 90 | 57 | 115 | 70 |

| 4 3/4 | 90 | 59 | 115 | 77 |

| 5 | 80 | 55 | 115 | 79 |

| 5 1/4 | 80 | 56 | 110 | 78 |

| 5 1/2 | 80 | 58 | 105 | 77 |

| 5 3/4 | 80 | 59 | 100 | 76 |

| 6 | 70 | 53 | 95 | 74 |

| DIAM: 3/4 | ||||

|---|---|---|---|---|

| LENGTH | BOLTS/KEG | LBS/KEG | BOLTS/KEG | LBS/KEG |

| 1 1/2 | 100 | 59 | 170 | 100 |

| 1 3/4 | 100 | 62 | 150 | 93 |

| 2 | 95 | 62 | 150 | 97 |

| 2 1/4 | 85 | 59 | 135 | 92 |

| 2 1/2 | 90 | 65 | 130 | 93 |

| 2 3/4 | 85 | 64 | 125 | 93 |

| 3 | 80 | 63 | 115 | 89 |

| 3 1/4 | 75 | 61 | 110 | 89 |

| 3 1/2 | 80 | 68 | 105 | 88 |

| 3 3/4 | 70 | 62 | 100 | 87 |

| 4 | 70 | 64 | 95 | 86 |

| 4 1/4 | 60 | 57 | 85 | 80 |

| 4 1/2 | 60 | 59 | 85 | 83 |

| 4 3/4 | 55 | 56 | 75 | 75 |

| 5 | 55 | 58 | 75 | 78 |

| 5 1/4 | 55 | 59 | 65 | 70 |

| 5 1/2 | 55 | 61 | 65 | 72 |

| 5 3/4 | 50 | 55 | 65 | 73 |

| 6 | 50 | 59 | 65 | 76 |

| 6 1/4 | 50 | 60 | 60 | 72 |

| 6 1/2 | 50 | 62 | 60 | 74 |

| 6 3/4 | 45 | 56 | 55 | 70 |

| 7 | 45 | 59 | 55 | 72 |

| 7 1/2 | 45 | 60 | 50 | 68 |

| 8 | 40 | 57 | 45 | 64 |

| 8 1/2 | 40 | 58 | 40 | 67 |

| DIAM: 7/8 | ||||

|---|---|---|---|---|

| LENGTH | BOLTS/KEG | LBS/KEG | BOLTS/KEG | LBS/KEG |

| 1 3/4 | 60 | 53 | 110 | 100 |

| 2 | 60 | 56 | 100 | 95 |

| 2 1/4 | 60 | 59 | 95 | 95 |

| 2 1/2 | 55 | 56 | 90 | 94 |

| 2 3/4 | 55 | 58 | 85 | 92 |

| 3 | 50 | 55 | 80 | 90 |

| 3 1/4 | 50 | 57 | 75 | 88 |

| 3 1/2 | 50 | 59 | 75 | 91 |

| 3 3/4 | 45 | 56 | 70 | 89 |

| 4 | 45 | 57 | 65 | 85 |

| 4 1/4 | 45 | 59 | 60 | 81 |

| 4 1/2 | 40 | 54 | 60 | 83 |

| 4 3/4 | 40 | 56 | 55 | 79 |

| 5 | 40 | 58 | 55 | 82 |

| 5 1/4 | 40 | 59 | 50 | 76 |

| 5 1/2 | 40 | 61 | 50 | 79 |

| 5 3/4 | 35 | 55 | 45 | 73 |

| 6 | 35 | 56 | 45 | 75 |

| DIAM: 1 | ||||

|---|---|---|---|---|

| LENGTH | BOLTS/KEG | LBS/KEG | BOLTS/KEG | LBS/KEG |

| 2 | 45 | 58 | 75 | 99 |

| 2 1/4 | 45 | 60 | 70 | 96 |

| 2 1/2 | 40 | 56 | 70 | 100 |

| 2 3/4 | 40 | 58 | 65 | 96 |

| 3 | 40 | 60 | 60 | 93 |

| 3 1/4 | 35 | 54 | 60 | 96 |

| 3 1/2 | 35 | 56 | 55 | 91 |

| 3 3/4 | 35 | 58 | 55 | 94 |

| 4 | 35 | 60 | 50 | 88 |

| 4 1/4 | 35 | 62 | 45 | 82 |

| 4 1/2 | 30 | 55 | 45 | 84 |

| 4 3/4 | 30 | 57 | 40 | 78 |

| 5 | 30 | 58 | 40 | 80 |

| 5 1/4 | 30 | 60 | 40 | 82 |

| 5 1/2 | 30 | 62 | 30 | 64 |

| 5 3/4 | 25 | 53 | 35 | 76 |

| 6 | 25 | 54 | 30 | 67 |

| 6 1/4 | 25 | 55 | 30 | 69 |

| 6 1/2 | 25 | 57 | 30 | 71 |

| DIAM: 1 1/8 | ||||

|---|---|---|---|---|

| LENGTH | BOLTS/KEG | LBS/KEG | BOLTS/KEG | LBS/KEG |

| 2 3/4 | 30 | 58 | 50 | 99 |

| 3 | 30 | 60 | 45 | 92 |

| 3 1/4 | 30 | 62 | 45 | 95 |

| 3 1/2 | 25 | 53 | 40 | 87 |

| 3 3/4 | 25 | 55 | 40 | 90 |

| 4 | 25 | 57 | 40 | 93 |

| 4 1/4 | 25 | 59 | 35 | 84 |

| 4 1/2 | 25 | 60 | 35 | 87 |

| 4 3/4 | 20 | 50 | 30 | 77 |

| 5 | 20 | 51 | 30 | 79 |

| 5 1/4 | 20 | 52 | 30 | 81 |

| 5 1/2 | 20 | 54 | 25 | 70 |

| 5 3/4 | 20 | 55 | 25 | 71 |

| 6 | 20 | 57 | 25 | 73 |

| 6 1/4 | 20 | 58 | 25 | 75 |

| 6 1/2 | 20 | 59 | 25 | 77 |

| 6 3/4 | 15 | 56 | 25 | 78 |

| 7 | 15 | 47 | 25 | 80 |

| 7 1/4 | 15 | 48 | 20 | 66 |

| 7 1/2 | 15 | 49 | 20 | 67 |

| DIAM: 1 1/4 | ||||

|---|---|---|---|---|

| LENGTH | BOLTS/KEG | LBS/KEG | BOLTS/KEG | LBS/KEG |

| 2 3/4 | N/A | N/A | 50 | 99 |

| 3 | N/A | N/A | 45 | 92 |

| 3 1/4 | N/A | N/A | 45 | 95 |

| 3 1/2 | N/A | N/A | 40 | 88 |

| 3 3/4 | N/A | N/A | 40 | 90 |

| 4 | N/A | N/A | 40 | 93 |

| 4 1/4 | N/A | N/A | 35 | 84 |

| 4 1/2 | N/A | N/A | 35 | 87 |

| 4 3/4 | N/A | N/A | 30 | 77 |

| 5 | N/A | N/A | 30 | 79 |

| 5 1/4 | N/A | N/A | 30 | 81 |

| 5 1/2 | N/A | N/A | 25 | 70 |

| 5 3/4 | N/A | N/A | 25 | 71 |

| 6 | N/A | N/A | 25 | 73 |

| 6 1/4 | N/A | N/A | 25 | 75 |

| 6 1/2 | N/A | N/A | 25 | 77 |

| 6 3/4 | N/A | N/A | 25 | 78 |

| 7 | N/A | N/A | 25 | 80 |

| 7 1/4 | N/A | N/A | 20 | 66 |

| 7 1/2 | N/A | N/A | 20 | 67 |

| DIAM: 1 1/2 | ||||

|---|---|---|---|---|

| LENGTH | BOLTS/KEG | LBS/KEG | BOLTS/KEG | LBS/KEG |

| 3 1/2 | N/A | N/A | 20 | 90 |

| 3 3/4 | N/A | N/A | 20 | 92 |

| 4 | N/A | N/A | 15 | 72 |

| 4 1/4 | N/A | N/A | 15 | 73 |

| 4 1/2 | N/A | N/A | 15 | 75 |

| 4 3/4 | N/A | N/A | 15 | 77 |

| 5 | N/A | N/A | 15 | 79 |

| 5 1/4 | N/A | N/A | 15 | 81 |

| 5 1/2 | N/A | N/A | 15 | 83 |

| 5 3/4 | N/A | N/A | 15 | 84 |

| 6 | N/A | N/A | 15 | 86 |

| 6 1/4 | N/A | N/A | 10 | 60 |

| 6 1/2 | N/A | N/A | 10 | 61 |

As per Section 16 of ASTM F3125/F3125-23, here’s a summary of the requirements for packaging and package marking of heavy hex bolts and twist-off bolt assemblies.

16. Packaging and Package Marking:

16.1 Packaging:

16.2 Package Marking:

| Gr.A490 & Gr.F2280 Chemical Requirements | ||

|---|---|---|

| Heat Analysis | Type 1 | Type 3 |

| Carbon or Alloy Steel With Or Without Boron | Based On Corrosion IndexB | |

| Carbon | 0.30 – 4.48C | 0.30 – 0.53 |

| Manganese | 0.60 min | 0.60 min |

| Phosphorus, max | 0.035 | 0.035 |

| Sulfur, max | 0.04 | 0.04 |

| Silicon | D | D |

| Boron | 0.003 max | D |

| Copper | D | 0.20 – 0.60 |

| Nickel | D | 0.20E min |

| Chromium | D | 0.45 min |

| Vanadium | D | D |

| Molybdenum | D | 0.10E min |

| Titanium | D | D |

| Gr.A490 & Gr.F2280 Mechanical Properties (Full Size Bolts) | |||||

|---|---|---|---|---|---|

| Diam. | Stress AreaA | Tensile min | Tensile max | Proof Load Length Measurement min | Alternative Proof Load Yield Strength Method min |

| In. | In2 | lbf | lbf | lbf | lbf |

| 1/2-13 UNC | 0.142 | 21,300 | 24,600 | 17,050 | 18,500 |

| 5/8-11 UNC | 0.226 | 33,900 | 39,100 | 27,100 | 29,400 |

| 3/4-10 UNC | 0.334 | 50,100 | 57,800 | 40,100 | 43,400 |

| 7/8-9 UNC | 0.462 | 69,300 | 79,950 | 55,450 | 60,100 |

| 1-8 UNC | 0.606 | 90,900 | 104,850 | 72,700 | 78,800 |

| 1 1/8-7 UNC | 0.763 | 114,450 | 132,000 | 91,550 | 99,200 |

| 1 1/4-7 UNC | 0.969 | 145,350 | 167,650 | 116,300 | 126,000 |

| 1 3/8-6 UNC | 1.155 | 173,250 | 199,850 | 138,600 | 150,200 |

| 1 1/2-6 UNC | 1.405 | 210,750 | 243,100 | 168,600 | 182,600 |

| Above values based on | – | 150 Ksi | 173 Ksi | 120 Ksi | 130 Ksi |

| Gr.A490 & Gr.F2280 Mechanical Properties (Specimen Machined Bolts) | ||||

|---|---|---|---|---|

| Tensile min. | Tensile max. | Yield min. | Elongation in 4D min % | Reduction of Area min % |

| 150 ksi | 173 ksi | 130 ksi | 14 | 40 |

| Gr.A490 & F2280 Hardness Requirements for bolts | |||

|---|---|---|---|

| Brinell HB | Rockwell HRC | ||

| Min | Max | Min | Max |

| 311 | 352 | 33 | 38 |

| Gr. A490 & Gr.F2280 Pre-tension Requirements by Strength and Diameter | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Bolt Diam. | 1/2 | 5/8 | 3/4 | 7/8 | 1 | 1 1/8 | 1 1/4 | 1 3/8 | 1 1/2 |

| Kip | 1 | 2 | 4 | 5 | 6 | 8 | 10 | 12 | 15 |

| lbf | 1,000 | 2,000 | 4,000 | 5,000 | 6,000 | 8,000 | 10,000 | 12,000 | 15,000 |

| Gr.A490 Min. Tension At Full Rotation | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Bolt Diam. | 1/2 | 5/8 | 3/4 | 7/8 | 1 | 1 1/8 | 1 1/4 | 1 3/8 | 1 1/2 |

| Kip | 17 | 28 | 40 | 56 | 74 | 92 | 117 | 139 | 170 |

| lbf | 17,000 | 28,000 | 40,000 | 56,000 | 74,000 | 92,000 | 117,000 | 139,000 | 170,000 |

| Maximum Permitted Torque For Gr.A490 at Minimum Design TensionA | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Bolt Diam. In. | 1/2 | 5/8 | 3/4 | 7/8 | 1 | 1 1/8 | 1 1/4 | 1 3/8 | 1 1/2 |

| Tension (Kips)A | 15 | 24 | 35 | 49 | 64 | 80 | 102 | 121 | 148 |

| Tension (lbf) | 15,000 | 24,000 | 35,000 | 49,000 | 64,000 | 80,000 | 102,000 | 121,000 | 148,000 |

| Max. Toque Ft.Lbs | 156 | 312 | 546 | 893 | 1,333 | 1,875 | 2,656 | 3,466 | 4,625 |

| Maximum Permitted Torque For Gr.A490 at Minimum Design Tension | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Bolt Diam. In. | 1/2 | 5/8 | 3/4 | 7/8 | 1 | 1 1/8 | 1 1/4 | 1 3/8 | 1 1/2 |

| Toque (Ft.Lbs) | 180 | 370 | 630 | 1,020 | 1,540 | 2,160 | 3,050 | 3,980 | 5,310 |

| Minimum Required Degrees Of Rotation For Gr.A490 | ||

|---|---|---|

| Up to 4D | >4D to 8D | >8D to 12D |

| 240 | 300 | 360 |

| Minimum Required Degrees of Rotation (A2.5) | ||

|---|---|---|

| Bolt Length | Up to and including 4D | Greater than 4D up to and including 8D |

| Required Rotation (All Grades) | 120 | 180 |

| Minimum Required Degrees of Rotation (A2.7) | ||

|---|---|---|

| Bolt Length | Up to and including 4D | Greater than 4D up to and including 8D |

| Required Rotation (150 ksi) | 90 | 120 |

| LOT SIZE | |||

|---|---|---|---|

| 1-50 | 1 | ||

| 51-280 | 2 | ||

| 281-3,200 | 3 | ||

| 3,201-35,000 | 4 | ||

| 35,001-150,000 | 5 | ||

| 150,001-500,000 | 6 | ||

| 500,001+ | 7 |

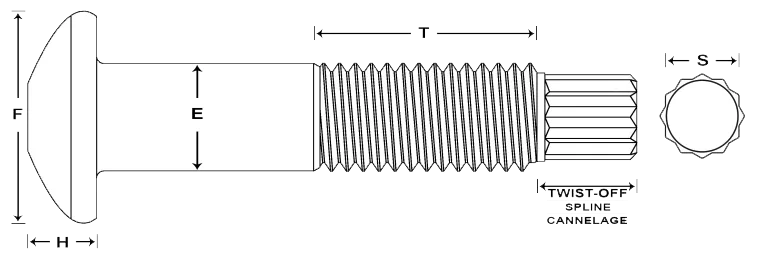

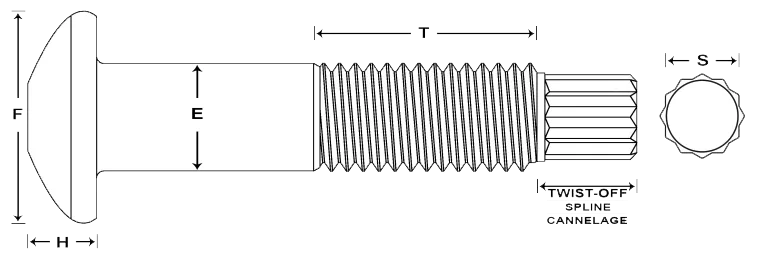

ASTM F3125 Grade F2280 fasteners, with a specified tensile strength of 150 ksi, are designed for high-strength structural applications. These bolts ensure reliable connections in critical assemblies, offering robust performance where strength and stability are paramount. To install F2280 fasteners accurately, an electric shear wrench is required to achieve proper tensioning. In various structural scenarios, ASTM F3125 Grade F2280 provides a dependable solution for achieving strong connections, contributing to the overall integrity of the structure.

Facilitating the selection of bolt length for a specific grip and bolt diameter is simplified by referring to the “Bolt Lengths for Various Grips” chart on page 6-167 in the Handbook of Steel Construction, 11th edition. This chart is relevant to the Imperial Series of ASTM F3125/F3125M bolts, including Grades A325/F1852 and A490/F2280 high-strength bolts used in bearing-type and slip-critical connections. It’s important to note that the provided bolt lengths may not automatically exclude bolt threads from the shear plane(s).

| Grip Inches | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1/2 | 5/8 | 3/4 | 7/8 | 1 | 1 1/8 | 1 1/4 | 1 3/8 | 1 1/2 | |

| 3/4 | 1 1/2 | 1 3/4 | *** | 2 | *** | *** | 2 1/2 | *** | 2 3/4 |

| 13/16 | 1 1/2 | 1 3/4 | 2 | 2 | 2 1/4 | 2 1/2 | 2 1/2 | 2 3/4 | 2 3/4 |

| 7/8 | 1 3/4 | 1 3/4 | 2 | 2 | 2 1/4 | 2 1/2 | 2 1/2 | 2 3/4 | 2 3/4 |

| 15/16 | 1 3/4 | 2 | 2 | 2 1/4 | 2 1/4 | 2 1/2 | 2 3/4 | 2 3/4 | 3 |

| 1 | 1 3/4 | 2 | 2 | 2 1/4 | 2 1/4 | 2 1/2 | 2 3/4 | 2 3/4 | 3 |

| 1 1/16 | 1 3/4 | 2 | 2 1/4 | 2 1/4 | 2 1/2 | 2 3/4 | 2 3/4 | 3 | 3 |

| 1 1/8 | 2 | 2 | 2 1/4 | 2 1/4 | 2 1/2 | 2 3/4 | 2 3/4 | 3 | 3 |

| 1 3/16 | 2 | 2 1/4 | 2 1/4 | 2 1/2 | 2 1/2 | 2 3/4 | 3 | 3 | 3 1/4 |

| 1 1/4 | 2 | 2 1/4 | 2 1/4 | 2 1/2 | 2 1/2 | 2 3/4 | 3 | 3 | 3 1/4 |

| 1 5/16 | 2 | 2 1/4 | 2 1/2 | 2 1/2 | 2 3/4 | 3 | 3 | 3 1/4 | 3 1/4 |

| 1 3/8 | 2 1/4 | 2 1/4 | 2 1/2 | 2 1/2 | 2 3/4 | 3 | 3 | 3 1/4 | 3 1/4 |

| 1 7/16 | 2 1/4 | 2 1/2 | 2 1/2 | 2 3/4 | 2 3/4 | 3 | 3 1/4 | 3 1/4 | 3 1/2 |

| 1 1/2 | 2 1/4 | 2 1/2 | 2 1/2 | 2 3/4 | 2 3/4 | 3 | 3 1/4 | 3 1/4 | 3 1/2 |

| 1 9/16 | 2 1/4 | 2 1/2 | 2 3/4 | 3 3/4 | 3 | 3 1/4 | 3 1/4 | 3 1/2 | 3 1/2 |

| 1 5/8 | 2 1/2 | 2 1/2 | 2 3/4 | 2 3/4 | 3 | 3 1/4 | 3 1/4 | 3 1/2 | 3 1/2 |

| 1 11/16 | 2 1/2 | 2 3/4 | 2 3/4 | 3 | 3 | 3 1/4 | 3 1/2 | 3 1/2 | 3 3/4 |

| 1 3/4 | 2 1/2 | 2 3/4 | 2 3/4 | 3 | 3 | 3 1/4 | 3 1/2 | 3 1/2 | 3 3/4 |

| 1 13/16 | 2 1/2 | 2 3/4 | 3 | 3 | 3 1/4 | 3 1/2 | 3 1/2 | 3 3/4 | 3 3/4 |

| 1 7/8 | 2 3/4 | 2 3/4 | 3 | 3 | 3 1/4 | 3 1/2 | 3 1/2 | 3 3/4 | 3 3/4 |

| 1 15/16 | 2 3/4 | 3 | 3 | 3 1/4 | 3 1/4 | 3 1/2 | 3 3/4 | 3 3/4 | 4 |

| 2 | 2 3/4 | 3 | 3 | 3 1/4 | 3 1/4 | 3 1/2 | 3 3/4 | 3 3/4 | 4 |

| 2 1/16 | 2 3/4 | 3 | 3 1/4 | 3 1/4 | 3 1/2 | 3 3/4 | 3 3/4 | 4 | 4 |

| 2 1/8 | 3 | 3 | 3 1/4 | 3 1/4 | 3 1/2 | 3 3/4 | 3 3/4 | 4 | 4 |

| 2 3/16 | 3 | 3 1/4 | 3 1/4 | 3 1/2 | 3 1/2 | 3 3/4 | 4 | 4 | 4 1/4 |

| 2 1/4 | 3 | 3 1/4 | 3 1/4 | 3 1/2 | 3 1/2 | 3 3/4 | 4 | 4 | 4 1/4 |

| 2 5/16 | 3 | 3 1/4 | 3 1/2 | 3 1/2 | 3 3/4 | 4 | 4 | 4 1/4 | 4 1/4 |

| 2 3/8 | 3 1/4 | 3 1/4 | 3 1/2 | 3 1/2 | 3 3/4 | 4 | 4 | 4 1/4 | 4 1/4 |

| 2 7/16 | 3 1/4 | 3 1/2 | 3 1/2 | 3 3/4 | 3 3/4 | 4 | 4 1/4 | 4 1/4 | 4 1/2 |

| 2 1/2 | 3 1/4 | 3 1/2 | 3 1/2 | 3 3/4 | 3 3/4 | 4 | 4 1/4 | 4 1/4 | 4 1/2 |

| 2 9/16 | 3 1/4 | 3 1/2 | 3 3/4 | 3 3/4 | 4 | 4 1/4 | 4 1/4 | 4 1/2 | 4 1/2 |

| 2 5/8 | 3 1/2 | 3 1/2 | 3 3/4 | 3 3/4 | 4 | 4 1/4 | 41/4 | 4 1/2 | 4 1/2 |

| 2 11/16 | 3 1/2 | 3 3/4 | 3 3/4 | 4 | 4 | 4 1/4 | 4 1/2 | 4 1/2 | 4 3/4 |

| 2 3/4 | 3 1/2 | 3 3/4 | 3 3/4 | 4 | 4 | 4 1/4 | 4 1/2 | 4 1/2 | 4 3/4 |

| 2 13/16 | 3 1/2 | 3 3/4 | 4 | 4 | 4 1/4 | 4 1/2 | 4 1/2 | 4 3/4 | 4 3/4 |

| 2 7/8 | 3 3/4 | 3 3/4 | 4 | 4 | 4 1/4 | 4 1/2 | 4 1/2 | 4 3/4 | 4 3/4 |

| 2 15/16 | 3 3/4 | 4 | 4 | 4 1/4 | 4 1/4 | 4 1/2 | 4 3/4 | 4 3/4 | 5 |

| 3 | 3 3/4 | 4 | 4 | 4 1/4 | 4 1/4 | 4 1/2 | 4 3/4 | 4 3/4 | 5 |

| 3 1/16 | 3 3/4 | 4 | 4 1/4 | 4 1/4 | 4 1/2 | 4 3/4 | 4 3/4 | 5 | 5 |

| 3 1/8 | 4 | 4 | 4 1/4 | 4 1/4 | 4 1/2 | 4 3/4 | 4 3/4 | 5 | 5 |

| 3 3/16 | 4 | 4 1/4 | 4 1/4 | 4 1/2 | 4 1/2 | 4 3/4 | 5 | 5 | 5 1/4 |

| 3 1/4 | 4 | 4 1/4 | 4 1/4 | 4 1/2 | 4 1/2 | 4 3/4 | 5 | 5 | 5 1/4 |

| 3 5/16 | 4 | 4 1/4 | 4 1/2 | 4 1/2 | 4 3/4 | 5 | 5 | 5 1/4 | 5 1/4 |

| 3 3/8 | 4 1/4 | 4 1/4 | 4 1/2 | 4 1/2 | 4 3/4 | 5 | 5 | 5 1/4 | 5 1/4 |

| 3 7/16 | 4 1/4 | 4 1/2 | 4 1/2 | 4 3/4 | 4 3/4 | 5 | 5 1/4 | 5 1/4 | 5 1/2 |

| 3 1/2 | 4 1/4 | 4 1/2 | 4 1/2 | 4 3/4 | 4 3/4 | 5 | 5 1/4 | 5 1/4 | 5 1/2 |

| 3 9/16 | 4 1/4 | 4 1/2 | 4 3/4 | 4 3/4 | 5 | 5 1/4 | 5 1/4 | 5 1/2 | 5 1/2 |

| 3 5/8 | 4 1/2 | 4 1/2 | 4 3/4 | 4 3/4 | 5 | 5 1/4 | 5 1/4 | 5 1/2 | 5 1/2 |

| 3 11/16 | 4 1/2 | 4 3/4 | 4 3/4 | 5 | 5 | 5 1/4 | 5 1/2 | 5 1/2 | 5 3/4 |

| 3 3/4 | 4 1/2 | 4 3/4 | 4 3/4 | 5 | 5 | 5 1/4 | 5 1/2 | 5 1/2 | 5 3/4 |

| 3 13/16 | 4 1/2 | 4 3/4 | 5 | 5 | 5 1/4 | 5 1/2 | 5 1/2 | 5 3/4 | 5 3/4 |

| 3 7/8 | 4 3/4 | 4 3/4 | 5 | 5 | 5 1/4 | 5 1/2 | 5 1/2 | 5 3/4 | 5 3/4 |

| 3 15/16 | 4 3/4 | 5 | 5 | 5 1/4 | 5 1/4 | 5 1/2 | 5 3/4 | 5 3/4 | 6 |

| 4 | 4 3/4 | 5 | 5 | 5 1/4 | 5 1/2 | 5 1/2 | 5 3/4 | 5 3/4 | 6 |

| 4 1/16 | 4 3/4 | 5 | 5 1/4 | 5 1/4 | 5 1/2 | 5 3/4 | 5 3/4 | 6 | 6 |

| Bolt Diam. | ||||||

|---|---|---|---|---|---|---|

| Body Diam. | Head Diam. | Height | Thread Length | Width Across Spline | ||

| Max | Max | Max | Min | Basic | Basic | |

| 5/8-11 | 0.642 | 1.313 | 0.403 | 0.378 | 1.25 | 0.43 |

| 3/4-10 | 0.768 | 1.58 | 0.483 | 0.455 | 1.38 | 0.53 |

| 7/8-9 | 0.895 | 1.88 | 0.563 | 0.531 | 1.5 | 0.61 |

| 1-8 | 1.022 | 2.158 | 0.627 | 0.591 | 1.75 | 0.7 |

| 1 1/8-7 | 1.149 | 2.375 | 0.718 | 0.658 | 2 | 0.8 |

| 1 1/4-7 | 1.277 | 2.76 | 0.813 | 0.749 | 2 | 0.4 |

| 1 3/8-6 | 1.404 | 2.91 | 0.878 | 0.81 | 2.25 | 1 |

| 1 1/2-6 | 1.531 | 3.16 | 0.974 | 0.902 | 2.25 | 1.1 |

| F3125 Grade F1852 Dimensions, Threads & Grade Marking | ||

|---|---|---|

| Type 1 | Type 3 | |

| Style – Twist-Off Bolts | ||

| Dimensions, ASMEB | B18.2.6 | B18.2.6 |

| Thread Fit, ASMEB | B1.1 UNC 2A | B1.1 UNC 2A |

| Grade MarkingA, D | A325TC | A325TC |

| Grade Alt. MarkingA, C | A325 | A325 |

| F3125 Gr.A490 & F2280 Matching Components | ||

|---|---|---|

| Type 1 | Type 3 | |

| Recommended Nut and Washer | ||

| Plain Nut | A563 DH | A563 DH3 |

| Suitable AlternativeE | – | – |

| Coated Nut | A563 DH | A563 DH3 |

| Flat, Bevel or Thick washer if used | F436-1 | F436-3 |

| 150 ksi Bolt AssembliesA | |||

|---|---|---|---|

| Qualified Coatings | Classification codes | ||

| Corrosion | Appearance | Coefficient of friction | |

| F3393 | D | 1 | RB |

*Note that Boulons Plus offer Gr.F2280 only in plain.

Features | F3125 KPF | F3125 Domestic |

|---|---|---|

Keg Material | Metal | Metal |

Keg Max Weight | 65 Lbs | 235 Lbs |

Come With Handle | ✔ | X |

Quickly Open/Seal Lid | ✔ | X |

Kegs Per Skid | 27 | 9 |

Keg Height | 8 1/4 inches | 20 inches |

Keg Visual |  |  |

| DIAM: 5/8 | ||||

|---|---|---|---|---|

| LENGTH | BOLTS/KEG | LBS/KEG | BOLTS/KEG | LBS/KEG |

| 1 1/2 | 150 | 57 | 500 | 204 |

| 1 3/4 | 140 | 57 | 470 | 206 |

| 2 | 140 | 60 | 450 | 206 |

| 2 1/4 | 130 | 57 | 410 | 196 |

| 2 1/2 | 120 | 56 | 380 | 190 |

| 2 3/4 | 110 | 54 | 350 | 182 |

| 3 | N/A | N/A | 325 | 176 |

| DIAM: 3/4 | ||||

|---|---|---|---|---|

| LENGTH | BOLTS/KEG | LBS/KEG | BOLTS/KEG | LBS/KEG |

| 1 3/4 | 95 | 59 | 300 | 205 |

| 2 | 90 | 59 | 280 | 200 |

| 2 1/4 | 85 | 58 | 270 | 200 |

| 2 1/2 | 80 | 57 | 250 | 194 |

| 2 3/4 | 80 | 59 | 250 | 201 |

| 3 | 75 | 58 | 240 | 203 |

| 3 1/4 | 75 | 60 | 230 | 202 |

| 3 1/2 | 70 | 58 | 220 | 200 |

| 3 3/4 | 70 | 60 | 200 | 188 |

| 4 | 70 | 63 | 190 | 184 |

| 4 1/2 | 60 | 57 | 180 | 187 |

| 4 3/4 | 60 | 59 | 160 | 172 |

| 5 | 60 | 61 | 150 | 166 |

| 5 1/2 | 50 | 53 | 140 | 163 |

| 6 | 50 | 57 | 130 | 161 |

| DIAM: 7/8 | ||||

|---|---|---|---|---|

| LENGTH | BOLTS/KEG | LBS/KEG | BOLTS/KEG | LBS/KEG |

| 2 | 60 | 57 | 200 | 206 |

| 2 1/4 | 60 | 59 | 190 | 203 |

| 2 1/2 | 55 | 57 | 180 | 202 |

| 2 3/4 | 55 | 59 | 180 | 209 |

| 3 | 50 | 56 | 170 | 204 |

| 3 1/4 | 50 | 58 | 160 | 201 |

| 3 1/2 | 50 | 60 | 150 | 194 |

| 3 3/4 | 45 | 56 | 140 | 187 |

| 4 | 45 | 58 | 140 | 194 |

| 4 1/4 | 40 | 54 | 130 | 186 |

| 4 1/2 | 40 | 54 | 120 | 177 |

| 4 3/4 | 30 | 42 | 120 | 183 |

| 5 | 30 | 43 | 115 | 180 |

| 5 1/2 | 30 | 47 | 100 | 166 |

| 6 | 30 | 49 | 95 | 166 |

| DIAM: 1 | ||||

|---|---|---|---|---|

| LENGTH | BOLTS/KEG | LBS/KEG | BOLTS/KEG | LBS/KEG |

| 2 | 45 | 59 | 150 | 214 |

| 2 1/4 | 45 | 61 | 140 | 204 |

| 2 1/2 | 40 | 56 | 130 | 197 |

| 2 3/4 | 40 | 58 | 130 | 204 |

| 3 | 40 | 60 | 120 | 196 |

| 3 1/4 | 35 | 55 | 120 | 203 |

| 3 1/2 | 35 | 57 | 110 | 192 |

| 3 3/4 | 35 | 58 | 110 | 198 |

| 4 | 35 | 60 | 100 | 187 |

| 4 1/4 | 30 | 54 | 90 | 173 |

| 4 1/2 | 30 | 55 | 90 | 178 |

| 4 3/4 | 30 | 57 | 90 | 183 |

| 5 | 30 | 58 | 85 | 178 |

| 5 1/2 | 25 | 51 | 80 | 177 |

| 6 | 25 | 54 | 70 | 163 |

| 6 1/2 | 25 | 57 | 65 | 156 |

| 7 | 20 | 48 | 60 | 145 |

| 7 1/2 | 20 | 50 | 55 | 135 |

| 8 | 20 | 53 | 55 | 135 |

| 8 1/2 | N/A | N/A | 50 | 123 |

| DIAM: 1 1/8 | ||||

|---|---|---|---|---|

| LENGTH | BOLTS/KEG | LBS/KEG | BOLTS/KEG | LBS/KEG |

| 2 3/4 | 30 | 58 | 80 | 184 |

| 3 | 30 | 61 | 80 | 189 |

| 3 1/4 | 30 | 63 | 70 | 172 |

| 3 1/2 | 25 | 54 | 70 | 175 |

| 3 3/4 | 25 | 56 | 70 | 183 |

| 4 | 25 | 57 | 70 | 186 |

| 4 1/4 | 25 | 59 | 60 | 165 |

| 4 1/2 | 25 | 61 | 60 | 168 |

| 4 3/4 | 20 | 50 | 50 | 146 |

| 5 | 20 | 51 | 50 | 148 |

| 5 1/2 | 20 | 54 | 50 | 155 |

| 6 | 20 | 57 | 50 | 162 |

| 6 1/2 | 20 | 59 | 50 | 169 |

| 7 | 15 | 47 | 40 | 141 |

| 7 1/2 | 15 | 49 | 40 | 147 |

| 8 | 15 | 51 | 40 | 147 |

| 8 1/2 | N/A | N/A | 35 | 134 |

| DIAM: 1 1/4 | ||||

|---|---|---|---|---|

| LENGTH | BOLTS/KEG | LBS/KEG | BOLTS/KEG | LBS/KEG |

| 3 | N/A | N/A | 80 | 219 |

| 3 1/4 | N/A | N/A | 80 | 226 |

| 3 1/2 | N/A | N/A | 80 | 233 |

| 3 3/4 | N/A | N/A | 70 | 210 |

| 4 | N/A | N/A | 70 | 217 |

| 4 1/4 | N/A | N/A | 70 | 222 |

| 4 1/2 | N/A | N/A | 60 | 196 |

| 4 3/4 | N/A | N/A | 60 | 201 |

| 5 | N/A | N/A | 50 | 173 |

| 5 1/2 | N/A | N/A | 50 | 181 |

| 6 | N/A | N/A | 50 | 190 |

| 6 1/2 | N/A | N/A | 50 | 199 |

| 7 | N/A | N/A | 45 | 187 |

| 7 1/2 | N/A | N/A | 40 | 173 |

| 8 | N/A | N/A | 40 | 180 |

| 8 1/2 | N/A | N/A | 40 | 187 |

| 9 | N/A | N/A | 35 | 170 |

| 9 1/2 | N/A | N/A | 30 | 152 |

As per Section 16 of ASTM F3125/F3125-23, here’s a summary of the requirements for packaging and package marking of heavy hex bolts and twist-off bolt assemblies.

16. Packaging and Package Marking:

16.1 Packaging:

16.2 Package Marking:

| Gr.A490 & Gr.F2280 Chemical Requirements | ||

|---|---|---|

| Heat Analysis | Type 1 | Type 3 |

| Carbon or Alloy Steel With Or Without Boron | Based On Corrosion IndexB | |

| Carbon | 0.30 – 4.48C | 0.30 – 0.53 |

| Manganese | 0.60 min | 0.60 min |

| Phosphorus, max | 0.035 | 0.035 |

| Sulfur, max | 0.04 | 0.04 |

| Silicon | D | D |

| Boron | 0.003 max | D |

| Copper | D | 0.20 – 0.60 |

| Nickel | D | 0.20E min |

| Chromium | D | 0.45 min |

| Vanadium | D | D |

| Molybdenum | D | 0.10E min |

| Titanium | D | D |

| Gr.A490 & Gr.F2280 Mechanical Properties (Full Size Bolts) | |||||

|---|---|---|---|---|---|

| Diam. | Stress AreaA | Tensile min | Tensile max | Proof Load Length Measurement min | Alternative Proof Load Yield Strength Method min |

| In. | In2 | lbf | lbf | lbf | lbf |

| 1/2-13 UNC | 0.142 | 21,300 | 24,600 | 17,050 | 18,500 |

| 5/8-11 UNC | 0.226 | 33,900 | 39,100 | 27,100 | 29,400 |

| 3/4-10 UNC | 0.334 | 50,100 | 57,800 | 40,100 | 43,400 |

| 7/8-9 UNC | 0.462 | 69,300 | 79,950 | 55,450 | 60,100 |

| 1-8 UNC | 0.606 | 90,900 | 104,850 | 72,700 | 78,800 |

| 1 1/8-7 UNC | 0.763 | 114,450 | 132,000 | 91,550 | 99,200 |

| 1 1/4-7 UNC | 0.969 | 145,350 | 167,650 | 116,300 | 126,000 |

| 1 3/8-6 UNC | 1.155 | 173,250 | 199,850 | 138,600 | 150,200 |

| 1 1/2-6 UNC | 1.405 | 210,750 | 243,100 | 168,600 | 182,600 |

| Above values based on | – | 150 Ksi | 173 Ksi | 120 Ksi | 130 Ksi |

| Gr.A490 & Gr.F2280 Mechanical Properties (Specimen Machined Bolts) | ||||

|---|---|---|---|---|

| Tensile min. | Tensile max. | Yield min. | Elongation in 4D min % | Reduction of Area min % |

| 150 ksi | 173 ksi | 130 ksi | 14 | 40 |

| Gr.A490 & F2280 Hardness Requirements for bolts | |||

|---|---|---|---|

| Brinell HB | Rockwell HRC | ||

| Min | Max | Min | Max |

| 311 | 352 | 33 | 38 |

| Gr. A490 & Gr.F2280 Pre-tension Requirements by Strength and Diameter | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Bolt Diam. | 1/2 | 5/8 | 3/4 | 7/8 | 1 | 1 1/8 | 1 1/4 | 1 3/8 | 1 1/2 |

| Kip | 1 | 2 | 4 | 5 | 6 | 8 | 10 | 12 | 15 |

| lbf | 1,000 | 2,000 | 4,000 | 5,000 | 6,000 | 8,000 | 10,000 | 12,000 | 15,000 |

| Gr. F2280 Assembly Min. Installation Tension | |||||||

|---|---|---|---|---|---|---|---|

| Bolt Diam. | 1/2 | 5/8 | 3/4 | 7/8 | 1 | 1 1/8 | 1 1/4 |

| lbf | 15,650 | 24,900 | 36,800 | 50,950 | 66,800 | 84,100 | 106,850 |

| LOT SIZE | |||

|---|---|---|---|

| 1-50 | 1 | ||

| 51-280 | 2 | ||

| 281-3,200 | 3 | ||

| 3,201-35,000 | 4 | ||

| 35,001-150,000 | 5 | ||

| 150,001-500,000 | 6 | ||

| 500,001+ | 7 |