Round bars compliant with CSA G40.21 Grade 50W are engineered for superior performance in structural applications, leveraging their high-strength, low-alloy composition to meet the stringent requirements of the Canadian Standards Association. This grade is characterized by its exceptional yield strength of 50 ksi, making it an ideal choice for projects demanding durability and resistance without the need for heat treatment. The precise chemical composition of Grade 50W ensures its suitability for use in a variety of environments, providing a reliable foundation for bridges, buildings, and infrastructure projects. This material’s adaptability and robustness make it a preferred option for engineers and architects who require materials that can withstand the rigors of construction while maintaining structural integrity over time. CSA G40.21 Grade 50W round bars epitomize the advancements in steel anchors, offering an optimal balance of strength, flexibility, and reliability for demanding structural applications.

50W or 350W?

In this CSA standard, measurements are expressed in SI (metric) units, with Anglo-Saxon (Imperial) values shown in brackets. Depending of the unit used, it is either known as 50W or 350W. This is the same steel expressed in different units

Available diameters: From 1/8 to 8 inches.

Default lengths: This material is generally supplied in 240-inch (20-foot) lengths. However, we can also manufacture custom lengths for your projects.

Please check with our account managers for availability and/or feasibility.

CSA G40.21 Grade 50W chemical & mechanical requirements are ruled by ASTM A6.

| Over | Under | ||

| To 5/16 | 0.005 | 0.005 | 0.008 |

| Over 5/16 to 7/16, incl | 0.006 | 0.006 | 0.009 |

| Over 7/16 to 5/8, incl | 0.007 | 0.007 | 0.01 |

| Over 5/8 to 7/8, incl | 0.008 | 0.008 | 0.012 |

| Over 7/8 to 1, incl | 0.009 | 0.009 | 0.013 |

| Over 1 to 1-1/8, incl | 0.01 | 0.01 | 0.015 |

| Over 1-1/8 to 1-1/4, incl | 0.011 | 0.011 | 0.016 |

| Over 1-1/4 to 1-3/8, incl | 0.012 | 0.012 | 0.018 |

| Over 1-3/8 to 1-1/2, incl | 0.014 | 0.014 | 0.021 |

| Over 1-1/2 to 2, incl | 1/64 | 1/64 | 0.023 |

| Over 2 to 2-1/2, incl | 1/32 | 0 | 0.023 |

| Over 2-1/2 to 3-1/2, incl | 3/64 | 0 | 0.035 |

| Over 3-1/2 to 4-1/2, incl | 1/16 | 0 | 0.046 |

| Over 4-1/2 to 5-1/2, incl | 5/64 | 0 | 0.058 |

| Over 5-1/2 to 6-1/2, incl | 1/8 | 0 | 0.07 |

| Over 6-1/2 to 8-1/4, incl | 5/32 | 0 | 0.085 |

| Over 8-1/4 to 9-1/2, incl | 3/16 | 0 | 0.1 |

| Over 9-1/2 to 10, incl | 1/4 | 0 | 0.12 |

The CSA G40.21 Grade 50W standard does not specify particular requirements for coating or finishing, leaving flexibility for different applications and preferences.

At Boulons Plus, we understand the importance of meeting diverse project needs and offer our clients the choice between bare steel and hot-dip galvanized finishes in compliance with ASTM F2329.

This option ensures that our clients can select the most suitable protection against corrosion and environmental wear for their specific application, ensuring longevity and durability in their projects.

| Chemical composition requirements for CSA G40.21 Gr.50W | |

|---|---|

| Chemical Elements | Heat Analysis % |

| Carbon | 0.23 |

| Manganese | 0.50-1.50 |

| Phosphorus | 0.04 max |

| Sulfur | 0.05 |

| Silicon(a)(b) | 0.40 max |

| Chromium | *** |

| Nickel | *** |

| Copperd | *** |

| Mechanical properties of bars & plates | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Grade, Imperial | Tensile strength, Ksi | Yield strength, ksi, minimum | Elongation*†, % minimum | ||||||

| Longitudinal | Transverse‡ | ||||||||

| ≤ 2 1/2 in | > 2 1/2 in ≤ 4 in | > 4 in ≤ 6 in | > 6 in ≤ 8 in | In 8 in | In 2 in | In 8 in | In 2 in | ||

| 50W | 65–95§ | 50 | 46 | 46 | 46 | 19 | 22 | 17 | 20 |

Round bars under the ASTM F1554 Grade 55 standard are recognized for their reliability, boasting a minimum yield strength of 55,000 psi. Available in plain steel and Hot Dip galvanized coatings, these bars, ranging from 1/2 to 4 inches in nominal diameter, offer sturdy solutions for construction and structural applications. The Grade 55 designation indicates a specific level of strength and ductility suitable for anchor bolts, threaded rods, and other fastening elements. Whether in plain steel for general applications or Hot Dip galvanized for enhanced corrosion resistance, these rods ensure secure connections in diverse environments, making them well-suited for construction projects and infrastructure development.

Diameter Availability: From 1/4 to 4 inches in diameter.

Thread Classes: This grade’s thread classes are of 2A class by default. (11.1.1: When an anchor bolt class is not specified, Class 2A shall be furnished.)

Default Lengths: This material is generally supplied in 240 inches (20 feet) and 288 inches (24 feet) lengths.

There is currently no coating reference table in ASTM F1554-20. However, section 7 give some details about coating:

7. Protective Coatings

7.1 Zinc, Hot Dip or Mechanically Deposited:

7.1.1 When zinc-coated anchor bolts are required, the purchaser shall specify the coating process, for example, hot dip, mechanically deposited, or no preference. When no preference is specified, the supplier may furnish bolts coated with either process. The supplier’s option is limited to one process per item, with no mixed processes in a lot.

7.1.2 When hot-dip zinc coated anchor bolts are specified, the anchor bolts and nuts shall be zinc-coated in accordance with the requirements of Specification F2329/F2329M.

7.1.3 When mechanically deposited zinc coated anchor bolts are provided, the anchor bolts and nuts shall be zinccoated in accordance with the requirements of Specification B695, Class 55.

7.1.4 Unless otherwise specified, when zinc-coated washers are required, the washers shall be hot-dip zinc-coated in accordance with Specification F2329/F2329M, or mechanically deposited zinc coated in accordance with Specification B695, Class 55. The coating process for the washers need not be the same as that for the anchor bolts and nuts.

7.2 Other Coatings:

7.2.1 When indicated on the inquiry and purchase order, coatings other than those in 7.1 shall be as agreed upon by the purchaser and supplier.

| ASTM F1554 Product Marking | |

|---|---|

| Grade | Color |

| 36 | Blue |

| 55 | Yellow |

| 55 (WeldableA) | Yellow (projecting end) & White (encased end) |

| 105 | Red |

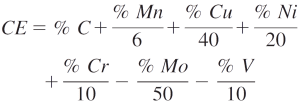

Calculus S1.4.2.1

Calculus S1.4.2.2

![]()

| S.1.41 – Steel shall conform to the following limitations: | ||

|---|---|---|

| Chemical Elements | Heat Analysis | Product Analysis |

| Carbon, max, % | 0.30 | 0.33 |

| Manganese, max % | 1.35 | 1.41 |

| Phosphorus, max, % | 0.040 | 0.048 |

| Sulfur, max, % | 0.050 | 0.058 |

| Silicon, max, % | 0.50 | 0.55 |

| Chemical Composition Requirements for ASTM F1554 Gr.55 & Gr.105 | ||

|---|---|---|

| Chemical Elements | Heat Analysis | Product Analysis |

| Carbon, max, % | *** | *** |

| Manganese, max % | *** | *** |

| Phosphorus, max, % | 0.04 | 0.048† |

| Sulfur, max, % | 0.05 | 0.058 |

| Copper, min, % (When specified) | 0.20 | 0.18 |

The table below only apply for Weldable Grade 55 Bars and Anchor Bolts as per supplementary Requirements S1.

| S.1.41 – Steel shall conform to the following limitations: | ||

|---|---|---|

| Chemical Elements | Heat Analysis | Product Analysis |

| Carbon, max, % | 0.30 | 0.33 |

| Manganese, max % | 1.35 | 1.41 |

| Phosphorus, max, % | 0.040 | 0.048 |

| Sulfur, max, % | 0.050 | 0.058 |

| Silicon, max, % | 0.50 | 0.55 |

| Axial Tensile Properties for Full-Size Tests of F1554-20 Gr.55 Anchor Bolts | |||

|---|---|---|---|

| Nominal Diam. | Stress Area, B, in.2. | Tensile Load, lbf | Yield min, lbf |

| 1/2 | 0.1419 | 10,600 – 13,500 | 7,800 |

| 5/8 | 0.226 | 17,000 – 21,500 | 12,400 |

| 3/4 | 0.334 | 25,000 – 31,700 | 18,400 |

| 7/8 | 0.462 | 34,600 – 43,900 | 25,400 |

| 1 | 0.606 | 45,400 – 57,600 | 33,300 |

| 1 1/8 | 0.763 | 57,200 – 72,500 | 42,000 |

| 1 1/4 | 0.969 | 72,700 – 92,100 | 53,300 |

| 1 1/2 | 1.405 | 105,000 – 133,000 | 77,300 |

| 1 3/4 | 1.90 | 142,000 – 180,000 | 104,500 |

| 2 | 2.50 | 188,000 – 238,000 | 138,000 |

| 2 1/4 | 3.25 | 244,000 – 309,000 | 179,000 |

| 2 1/2 | 4.00 | 300,000 – 380,000 | 220,000 |

| 2 3/4 | 4.93 | 370,000 – 468,000 | 271,000 |

| 3 | 5.97 | 448,000 – 567,000 | 328,000 |

| 3 1/4 | 7.10 | 532,000 – 674,000 | 390,000 |

| 3 1/2 | 8.33 | 625,000 – 791,000 | 458,000 |

| 3 3/4 | 9.66 | 724,000 – 918,000 | 531,000 |

| 4 | 11.08 | 831,000 – 1,053,000 | 609,000 |

| Tensile Properties for Bars and Machined Specimens for F1554 Gr.55 | |

|---|---|

| Tensile strength, KSI | 75 – 95 |

| Yield strength, min, ksi (0.2% offset) | 55 |

| Elongation in 8 in. , min, %A | 18 |

| Elongation in 2 in. min, %A | 21 |

| Reduction of Area, min, % | 30 |

Round bars under the ASTM F1554 Grade 105 standard represent a high-strength and robust option, featuring a minimum yield strength of 105,000 psi. Available in plain steel and Hot Dip galvanized coatings, these bars, ranging from 1/2 to 4 inches in nominal diameter, provide exceptional performance for critical applications in construction and structural engineering. The Grade 105 designation signifies superior strength and durability, making these bars suitable for demanding applications where high tensile strength and resistance to stress are essential. Whether in plain steel for general use or Hot Dip galvanized for enhanced corrosion resistance, ASTM F1554 Grade 105 round bars offer reliable support for heavy-duty construction projects. Their significant strength and durability make them an excellent choice for structural components, reinforcement, and other applications requiring a high degree of mechanical robustness

Diameter Availability: From 1/4 to 4 inches in diameter.

Thread Classes: This grade’s thread classes are of 2A class by default. (11.1.1: When an anchor bolt class is not specified, Class 2A shall be furnished.)

Default Lengths: This material is generally supplied in 240 inches (20 feet) and 288 inches (24 feet) lengths. If required, we can also manufacture custom lengths for your projects.

Please validate availability or feasibility with our account managers.

There is currently no coating reference table in ASTM F1554-20. However, section 7 give some details about coating:

7. Protective Coatings

7.1 Zinc, Hot Dip or Mechanically Deposited:

7.1.1 When zinc-coated anchor bolts are required, the purchaser shall specify the coating process, for example, hot dip, mechanically deposited, or no preference. When no preference is specified, the supplier may furnish bolts coated with either process. The supplier’s option is limited to one process per item, with no mixed processes in a lot.

7.1.2 When hot-dip zinc coated anchor bolts are specified, the anchor bolts and nuts shall be zinc-coated in accordance with the requirements of Specification F2329/F2329M.

7.1.3 When mechanically deposited zinc coated anchor bolts are provided, the anchor bolts and nuts shall be zinccoated in accordance with the requirements of Specification B695, Class 55.

7.1.4 Unless otherwise specified, when zinc-coated washers are required, the washers shall be hot-dip zinc-coated in accordance with Specification F2329/F2329M, or mechanically deposited zinc coated in accordance with Specification B695, Class 55. The coating process for the washers need not be the same as that for the anchor bolts and nuts.

7.2 Other Coatings:

7.2.1 When indicated on the inquiry and purchase order, coatings other than those in 7.1 shall be as agreed upon by the purchaser and supplier.

| ASTM F1554 Product Marking | |

|---|---|

| Grade | Color |

| 36 | Blue |

| 55 | Yellow |

| 55 (WeldableA) | Yellow (projecting end) & White (encased end) |

| 105 | Red |

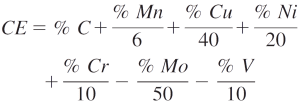

Calculus S1.4.2.1

Calculus S1.4.2.2

![]()

| S.1.41 – Steel shall conform to the following limitations: | ||

|---|---|---|

| Chemical Elements | Heat Analysis | Product Analysis |

| Carbon, max, % | 0.30 | 0.33 |

| Manganese, max % | 1.35 | 1.41 |

| Phosphorus, max, % | 0.040 | 0.048 |

| Sulfur, max, % | 0.050 | 0.058 |

| Silicon, max, % | 0.50 | 0.55 |

| Chemical Composition Requirements for ASTM F1554 Gr.55 & Gr.105 | ||

|---|---|---|

| Chemical Elements | Heat Analysis | Product Analysis |

| Carbon, max, % | *** | *** |

| Manganese, max % | *** | *** |

| Phosphorus, max, % | 0.04 | 0.048† |

| Sulfur, max, % | 0.05 | 0.058 |

| Copper, min, % (When specified) | 0.20 | 0.18 |

| Axial Tensile Properties for Full-Size Tests of F1554-20 Gr.105 Anchor Bolts | |||

|---|---|---|---|

| Nominal Diam. | Stress Area, B, in.2. | Tensile Load, lbf | Yield min, lbf |

| 1/2 | 0.1419 | 17,700 – 21,300 | 14,900 |

| 5/8 | 0.226 | 28,200 – 33,900 | 23,700 |

| 3/4 | 0.334 | 41,800 – 50,100 | 35,100 |

| 7/8 | 0.462 | 57,800 – 69,300 | 48,500 |

| 1 | 0.606 | 75,800 – 90,900 | 63,600 |

| 1 1/8 | 0.763 | 95,400 – 114,400 | 80,100 |

| 1 1/4 | 0.969 | 121,000 – 145,000 | 102,000 |

| 1 1/2 | 1.405 | 176,000 – 216,000 | 148,000 |

| 1 3/4 | 1.90 | 238,000 – 285,000 | 200,000 |

| 2 | 2.50 | 312,000 – 375,000 | 262,000 |

| 2 1/4 | 3.25 | 406,000 – 488,000 | 341,000 |

| 2 1/2 | 4.00 | 500,000 – 600,000 | 420,000 |

| 2 3/4 | 4.93 | 616,000 – 740,000 | 518,000 |

| 3 | 5.97 | 746,000 – 896,000 | 627,000 |

| 3 1/4 | 7.10 | — | — |

| 3 1/2 | 8.33 | — | — |

| 3 3/4 | 9.66 | — | — |

| 4 | 11.08 | — | — |

| Tensile Properties for Bars and Machined Specimens for F1554 Gr.105 | |

|---|---|

| Tensile strength, KSI | 125 – 150 |

| Yield strength, min, ksi (0.2% offset) | 105 |

| Elongation in 8 in. , min, %A | 12 |

| Elongation in 2 in. min, %A | 15 |

| Reduction of Area, min, % | 45 |