ASTM F959 DTI Washers, crucial for Type 325-1 and 325-3 applications, present versatile options. Type 1, available in plain or HDG F2329, ensures reliability with or without the optional squirter feature, aiding visual tension confirmation. Type 3, crafted from weathering steel, enhances durability for outdoor projects. Widely used in construction, bridges, and heavy-duty structures, these washers ensure precise preload, enhancing structural reliability. Type 325-1 focuses on coating, while Type 325-3 provides weathering resistance, ideal for demanding environments.

*For Weather resistance, see Type 3 products

As per ASTM F959/F959M-17

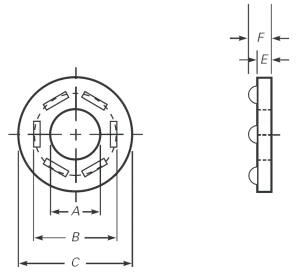

Section 7. Dimensions

7.1 Except as permitted by 7.1.1 and 7.1.2 the DTIs shall conform to the dimensional and related requirements of ASME B18.2.6 for inch series products.

7.1.1 At the manufacture’s discretion, the number of protrusions may be altered provided there are no fewer than four protrusions and the performance requirements of Section 6 are maintained.

7.1.2 The minimum outside diameter of the DTIs may alternatively match the minimum outside diameter requirements of the matching nominal size ASTM F436/F436M washer.

| Table 6 Dimensions for Compressible Washer-Type Direct Tensions Indicators | ||||||||

|---|---|---|---|---|---|---|---|---|

| Nom. Washer size, in. [Note (1)] | All Types | Type A325 | ||||||

| Inside Diameter, in., A | Protusion Tangential Diameter, in., B | Outside Diameter, In., C | Number of Protrusions (Equally Spaced) | Thickness, in. | ||||

| Without Protrusion, E | With Protrusion, F | |||||||

| Min. | Max. | Max. | Min. | Max. | Min. | Max. | ||

| 1/2 | 0.523 | 0.527 | 0.788 | 1.167 | 1.187 | 4 | 0.104 | 0.180 |

| 5/8 | 0.654 | 0.658 | 0.956 | 1.355 | 1.375 | 4 | 0.126 | 0.220 |

| 3/4 | 0.786 | 0.790 | 1.125 | 1.605 | 1.625 | 5 | 0.126 | 0.230 |

| 7/8 | 0.917 | 0.921 | 1.294 | 1.855 | 1.875 | 5 | 0.142 | 0.240 |

| 1 | 1.048 | 1.052 | 1.469 | 1.980 | 2.000 | 6 | 0.158 | 0.270 |

| 1 1/8 | 1.179 | 1.183 | 1.631 | 2.230 | 2.250 | 6 | 0.158 | 0.270 |

| 1 1/4 | 1.311 | 1.315 | 1.800 | 2.480 | 2.500 | 7 | 0.158 | 0.270 |

| 1 3/8 | 1.442 | 1.446 | 1.969 | 2.730 | 2.750 | 7 | 0.158 | 0.270 |

| 1 1/2 | 1.573 | 1.577 | 2.138 | 2.980 | 3.000 | 8 | 0.158 | 0.270 |

ASTM F959/F959M-17 Does not provide any table about coatings.

However, Section 4.4 give some details:

4.4 Protective Coatings:

4.4.1 Unless otherwise specified, the DTIs shall be furnished “plain” with the “as fabricated” surface finish without protective coatings.

4.4.2 When “zinc coated” or “galvanized” is specified, the DTIs shall be zinc coated by the mechanical deposition process in accordance with the requirements of Class 55 of Specification B695, or the DTIs shall be zinc coated by the thermal diffusion process in accordance with the requirements of Class 25 of Specification A1059.

4.4.3 Other coatings are to be used only when approved by the DTI manufacturer.

| Chemical Composition Requirements | ||||

|---|---|---|---|---|

| Elements | Composition % | |||

| Heat Analisys | Product Analisys | |||

| Type 1 Series | Type 3 SeriesA | Type 1 Series | Type 3 SeriesA | |

| Carbon | 0.30 – 0.55 | — | 0.27 – 0.58 | — |

| Manganese | 0.50 – 0.90 | — | 0.47 – 0.93 | — |

| Phosphorus, Max | 0.04 | 0.04 | 0.048 | 0.045 |

| Sulfur, Max | 0.05 | 0.05 | 0.053 | 0.055 |

| Silicon | — | 0.15 – 0.35 | — | 0.13 – 0.37 |

| Chromium | — | 0.45 – 0.65 | — | 0.42 – 0.68 |

| Nickel | — | 0.25 – 0.45 | — | 0.22 – 0.48 |

| Copper | — | 0.25 – 0.45 | — | 0.22 – 0.48 |

| Acceptable Range of Compression Loads | |

|---|---|

| DTI Size (Nom. Diam. In.) | Compression Load Range in Thousands of Pounds, (kips) |

| Types 325 and 325-3 | |

| 1/2 | 12 – 14 |

| 5/8 | 19 – 23 |

| 3/4 | 28 – 34 |

| 7/8 | 39 – 47 |

| 1 | 51 – 61 |

| 1 1/8 | 64 – 77 |

| 1 1/4 | 81 – 98 |

| 1 3/8 | 97 – 117 |

| 1 1/2 | 118 – 143 |

ASTM F959 DTI Washers, crucial for Type 490-1 and 490-3 applications, present versatile options. Type 1, available in plain steel, ensures reliability with or without the optional squirter feature, aiding visual tension confirmation. Type 3, crafted from weathering steel, enhances durability for outdoor projects. Widely used in construction, bridges, and heavy-duty structures, these washers ensure precise preload, enhancing structural reliability. With a focus on enhanced load-bearing capacity and reliability in challenging environments, Type 490-1 and 490-3 offer valuable options for critical infrastructure.

*For Weather resistance, see Type 3 products

As per ASTM F959/F959M-17

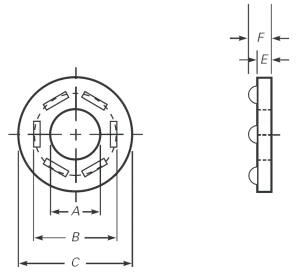

Section 7. Dimensions

7.1 Except as permitted by 7.1.1 and 7.1.2 the DTIs shall conform to the dimensional and related requirements of ASME B18.2.6 for inch series products.

7.1.1 At the manufacture’s discretion, the number of protrusions may be altered provided there are no fewer than four protrusions and the performance requirements of Section 6 are maintained.

7.1.2 The minimum outside diameter of the DTIs may alternatively match the minimum outside diameter requirements of the matching nominal size ASTM F436/F436M washer.

| Table 6 Dimensions for Compressible Washer-Type Direct Tensions Indicators | ||||||||

|---|---|---|---|---|---|---|---|---|

| Nom. Washer size, in. [Note (1)] | All Types | Type A490 | ||||||

| Inside Diameter, in., A | Protusion Tangential Diameter, in., B | Outside Diameter, In., C | Number of Protrusions (Equally Spaced) | Thickness, in. | ||||

| Without Protrusion, E | With Protrusion, F | |||||||

| Min. | Max. | Max. | Min. | Max. | Min. | Max. | ||

| 1/2 | 0.523 | 0.527 | 0.788 | 1.355 | 1.375 | 5 | 1.104 | 0.180 |

| 5/8 | 0.654 | 0.658 | 0.956 | 1.605 | 1.625 | 5 | 0.126 | 0.220 |

| 3/4 | 0.786 | 0.790 | 1.125 | 1.730 | 1.750 | 6 | 0.142 | 0.240 |

| 7/8 | 0.917 | 0.921 | 1.294 | 1.980 | 2.000 | 6 | 0.158 | 0.260 |

| 1 | 1.048 | 1.052 | 1.469 | 2.230 | 2.250 | 7 | 0.158 | 0.270 |

| 1 1/8 | 1.179 | 1.183 | 1.631 | 2.480 | 2.500 | 7 | 0.158 | 0.280 |

| 1 1/4 | 1.311 | 1.315 | 1.800 | 2.730 | 2.750 | 8 | 0.158 | 0.280 |

| 1 3/8 | 1.442 | 1.446 | 1.969 | 2.980 | 3.000 | 8 | 0.158 | 0.280 |

| 1 1/2 | 1.573 | 1.577 | 2.138 | 3.230 | 3.250 | 9 | 0.158 | 0.280 |

ASTM F959/F959M-17 Does not provide any table about coatings.

However, Section 4.4 give some details:

4.4 Protective Coatings:

4.4.1 Unless otherwise specified, the DTIs shall be furnished “plain” with the “as fabricated” surface finish without protective coatings.

4.4.2 When “zinc coated” or “galvanized” is specified, the DTIs shall be zinc coated by the mechanical deposition process in accordance with the requirements of Class 55 of Specification B695, or the DTIs shall be zinc coated by the thermal diffusion process in accordance with the requirements of Class 25 of Specification A1059.

4.4.3 Other coatings are to be used only when approved by the DTI manufacturer.

| Chemical Composition Requirements | ||||

|---|---|---|---|---|

| Elements | Composition % | |||

| Heat Analisys | Product Analisys | |||

| Type 1 Series | Type 3 SeriesA | Type 1 Series | Type 3 SeriesA | |

| Carbon | 0.30 – 0.55 | — | 0.27 – 0.58 | — |

| Manganese | 0.50 – 0.90 | — | 0.47 – 0.93 | — |

| Phosphorus, Max | 0.04 | 0.04 | 0.048 | 0.045 |

| Sulfur, Max | 0.05 | 0.05 | 0.053 | 0.055 |

| Silicon | — | 0.15 – 0.35 | — | 0.13 – 0.37 |

| Chromium | — | 0.45 – 0.65 | — | 0.42 – 0.68 |

| Nickel | — | 0.25 – 0.45 | — | 0.22 – 0.48 |

| Copper | — | 0.25 – 0.45 | — | 0.22 – 0.48 |

| Acceptable Range of Compression Loads | |

|---|---|

| DTI Size (Nom. Diam. In.) | Compression Load Range in Thousands of Pounds, (kips) |

| Types 490 and 490-3 | |

| 1/2 | 15 – 18 |

| 5/8 | 24 – 29 |

| 3/4 | 35 – 42 |

| 7/8 | 49 – 59 |

| 1 | 64 – 77 |

| 1 1/8 | 80 – 96 |

| 1 1/4 | 102 -122 |

| 1 3/8 | 121 – 145 |

| 1 1/2 | 148 – 178 |