ASTM A563 Grade DH and Grade DH3 are essential fastener materials in construction, tailored to specific engineering requirements. Grade DH features a medium carbon and alloy steel composition, striking a balance between strength and ductility. Grade DH3, a weathering steel variant, prioritizes corrosion resistance. These grades play a crucial role in ensuring robust connections for structural integrity in various construction projects, making them indispensable for applications in critical infrastructure such as building and anchoring.

*For Weather resistance, see Gr.DH3 products

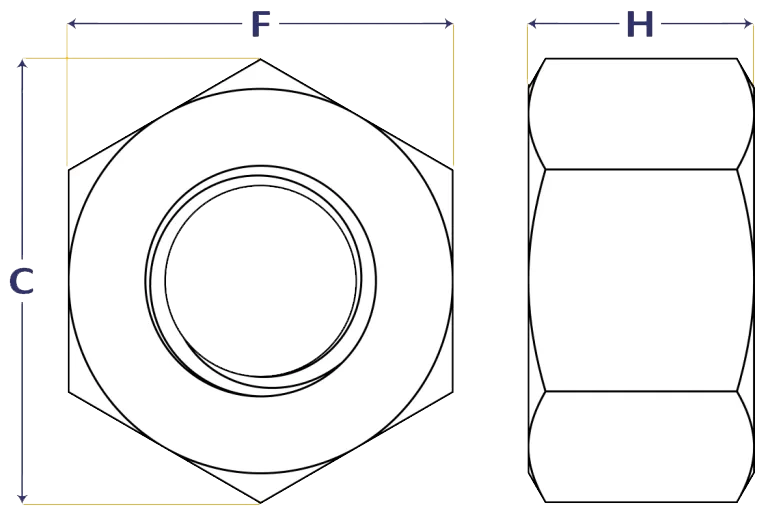

| Nominal Size | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Width Across Flats | Width Across Corners | Thickness | |||||||

| Basic | Max | Min | Max | Min | Basic | Max | Min | ||

| 1/4 | 1/2 | 0.5 | 0.488 | 0.577 | 0.556 | 15/64 | 0.25 | 0.218 | 1 |

| 5//16 | 9/16 | 0.562 | 0.546 | 0.65 | 0.622 | 16/64 | 0.341 | 0.28 | 2 |

| 3/8 | 11/16 | 0.688 | 0.669 | 0.794 | 0.763 | 23/64 | 0.377 | 0.341 | 3 |

| 1/2 | 7/8 | 0.875 | 0.85 | 1.01 | 0.969 | 31/64 | 0.504 | 0.464 | 7 |

| 5/8 | 1 1/16 | 1.062 | 1.031 | 1.227 | 1.175 | 39/64 | 0.631 | 0.587 | 12 |

| 3/4 | 1 1/4 | 1.25 | 1.212 | 1.443 | 1.382 | 47/64 | 0.758 | 0.71 | 20 |

| 7/8 | 1 7/16 | 1.438 | 1.394 | 1.66 | 1.589 | 54/64 | 0.885 | 0.833 | 30 |

| 1 | 1 5/8 | 1.625 | 1.575 | 1.876 | 1.796 | 63/64 | 1.012 | 0.956 | 43 |

| 1 1/8 | 1 13/16 | 1.812 | 1.756 | 2.093 | 2.002 | 1 7/64 | 1.139 | 1.079 | 59 |

| 1 1/4 | 2 | 2 | 1.938 | 2.309 | 2.209 | 1 7/32 | 1.251 | 1.187 | 79 |

| 1 3/8 | 2 3/16 | 2.188 | 2.119 | 2.526 | 2.416 | 1 11/32 | 1.378 | 1.31 | 102 |

| 1 1/2 | 2 3/8 | 2.375 | 2.3 | 2.742 | 2.622 | 1 15/32 | 1.505 | 1.433 | 131 |

| 1 5/8 | 2 9/16 | 2.562 | 2.481 | 2.959 | 2.828 | 1 19/32 | 1.632 | 1.556 | 162 |

| 1 3/4 | 2 3/4 | 2.75 | 2.662 | 3.175 | 3.035 | 1 23/32 | 1.759 | 1.679 | 204 |

| 1 7/8 | 2 15/16 | 2.938 | 2.844 | 3.392 | 3.242 | 1 27/32 | 1.886 | 1.802 | 241 |

| 2 | 3 1/8 | 3.125 | 3.025 | 3.608 | 3.449 | 1 31/32 | 2.013 | 1.925 | 299 |

| 2 1/4 | 3 1/2 | 3.5 | 3.388 | 4.041 | 3.862 | 2 13/64 | 2.251 | 2.155 | 419 |

| 2 1/2 | 3 7/8 | 3.875 | 3.75 | 4.474 | 4.275 | 2 29/64 | 2.505 | 2.401 | 564 |

| 2 3/4 | 4 1/4 | 4.25 | 4.112 | 4.907 | 4.688 | 2 45/64 | 2.759 | 2.647 | 738 |

| 3 | 4 5/8 | 4.625 | 4.475 | 5.34 | 5.102 | 2 61/64 | 3.013 | 2.893 | 950 |

| 3 1/4 | 5 | 5 | 4.838 | 5.774 | 5.514 | 3 3/16 | 3.252 | 3.124 | 1,194 |

| 3 1/2 | 5 3/8 | 5.375 | 5.2 | 6.207 | 5.928 | 3 7/16 | 3.506 | 3.37 | 1,526 |

| 3 3/4 | 5 3/4 | 5.75 | 5.562 | 6.64 | 6.341 | 3 11/16 | 3.76 | 3.616 | 1,812 |

| 4 | 6 1/8 | 6.125 | 5.925 | 7.073 | 6.755 | 3 15/16 | 4.014 | 3.862 | 2,180 |

| Commonly Applied Coatings (A1.1) | ||

|---|---|---|

| Coating Type | Specification | Grade or Class |

| Hot-dip zinc | F2329 | 0.002 in. (50 μm) |

| Mechanically deposited zinc | B695 | Class 55 |

| Zn/Al Coating | F1136 | Grade 5 |

| Zn/Al Coating | F2833 | Grade 1 |

| Zn/Al Coating | F3019 | Grade 4 |

| Zn/Al Coating | F3393 | – |

| Zinc Electroplate | F1941 | Fe/Zn 5AN & Fe/Zn 5C |

| A563 DH/DH3 Chemical RequirementsA | |||

|---|---|---|---|

| Heat Analysis | DH | DH3 | |

| Composition % | Composition % | Based On Corrosion IndexC | |

| Carbon | 0.20 – 0.55 | 0.20 – 0.53 | 0.30 – 0.53 |

| Manganese | 0.60 min | 0.40 min | 0.60 min |

| Phosphorus, max | 0.04 | 0.035 | 0.035 |

| Sulfur, max | 0.05E | 0.040 | 0.040 |

| Silicon | B | B | B |

| Copper | B | 0.20 min | 0.20 – 0.60 |

| Nickel | B | 0.20 min | 0.20F min |

| Chromium | B | 0.45 min | 0.45 min |

| Vanadium | B | B | B |

| Molybdenum | B | 0.15 min | 0.10F min |

| Titanium | B | B | B |

| Mechanical Requirements for Gr.DH & DH3 | ||||||||

|---|---|---|---|---|---|---|---|---|

| Grade of Nut | Nom. Nut Size in. | Style of Nut | Proof Load Stress, ksiA | Hardness | ||||

| Non-Zinc-Coated NutsB | Zinc-Coated NutsB | Brinell | Rockwell | |||||

| min | max | min | max | |||||

| DHD | 1/4 to 4 | Heavy Hex | 175 | 150F† | 248 | 352 | C24 | C38 |

| DH3 | 1/4 to 4 | Heavy Hex | 175 | 150F† | 248 | 352 | C24 | C38 |

ASTM A563 Grade C nuts are integral in high-strength applications, forged from carbon steel for exceptional durability. Heat-treated for robustness, they excel in demanding environments. Available with coatings such as plain steel or hot-dip galvanized, in line with ASTM F2329 standards, these nuts provide versatility. Widely applied in industries like construction and machinery, they conform to ASTM A563 Grade C standards, ensuring reliable quality. Ideal for secure fastening in challenging conditions, they stand as a trusted choice for durable projects.

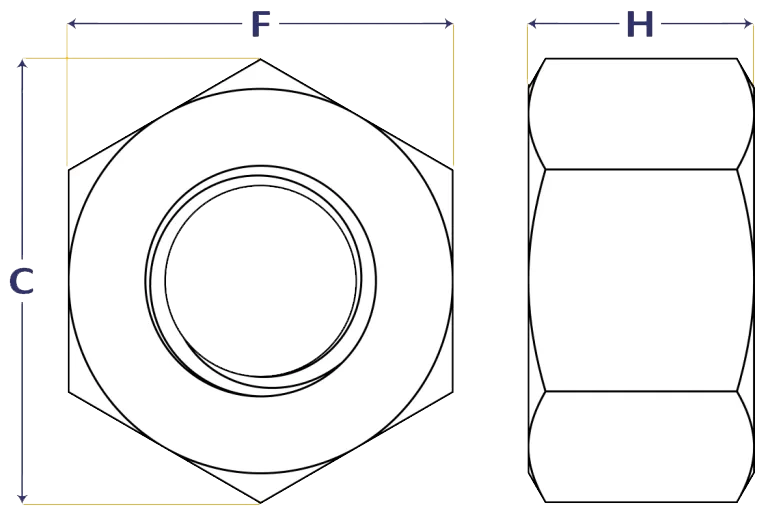

| Nominal Size | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Width Across Flats | Width Across Corners | Thickness | |||||||

| Basic | Max | Min | Max | Min | Basic | Max | Min | ||

| 1/4 | 1/2 | 0.5 | 0.488 | 0.577 | 0.556 | 15/64 | 0.25 | 0.218 | 1 |

| 5//16 | 9/16 | 0.562 | 0.546 | 0.65 | 0.622 | 16/64 | 0.341 | 0.28 | 2 |

| 3/8 | 11/16 | 0.688 | 0.669 | 0.794 | 0.763 | 23/64 | 0.377 | 0.341 | 3 |

| 1/2 | 7/8 | 0.875 | 0.85 | 1.01 | 0.969 | 31/64 | 0.504 | 0.464 | 7 |

| 5/8 | 1 1/16 | 1.062 | 1.031 | 1.227 | 1.175 | 39/64 | 0.631 | 0.587 | 12 |

| 3/4 | 1 1/4 | 1.25 | 1.212 | 1.443 | 1.382 | 47/64 | 0.758 | 0.71 | 20 |

| 7/8 | 1 7/16 | 1.438 | 1.394 | 1.66 | 1.589 | 54/64 | 0.885 | 0.833 | 30 |

| 1 | 1 5/8 | 1.625 | 1.575 | 1.876 | 1.796 | 63/64 | 1.012 | 0.956 | 43 |

| 1 1/8 | 1 13/16 | 1.812 | 1.756 | 2.093 | 2.002 | 1 7/64 | 1.139 | 1.079 | 59 |

| 1 1/4 | 2 | 2 | 1.938 | 2.309 | 2.209 | 1 7/32 | 1.251 | 1.187 | 79 |

| 1 3/8 | 2 3/16 | 2.188 | 2.119 | 2.526 | 2.416 | 1 11/32 | 1.378 | 1.31 | 102 |

| 1 1/2 | 2 3/8 | 2.375 | 2.3 | 2.742 | 2.622 | 1 15/32 | 1.505 | 1.433 | 131 |

| 1 5/8 | 2 9/16 | 2.562 | 2.481 | 2.959 | 2.828 | 1 19/32 | 1.632 | 1.556 | 162 |

| 1 3/4 | 2 3/4 | 2.75 | 2.662 | 3.175 | 3.035 | 1 23/32 | 1.759 | 1.679 | 204 |

| 1 7/8 | 2 15/16 | 2.938 | 2.844 | 3.392 | 3.242 | 1 27/32 | 1.886 | 1.802 | 241 |

| 2 | 3 1/8 | 3.125 | 3.025 | 3.608 | 3.449 | 1 31/32 | 2.013 | 1.925 | 299 |

| 2 1/4 | 3 1/2 | 3.5 | 3.388 | 4.041 | 3.862 | 2 13/64 | 2.251 | 2.155 | 419 |

| 2 1/2 | 3 7/8 | 3.875 | 3.75 | 4.474 | 4.275 | 2 29/64 | 2.505 | 2.401 | 564 |

| 2 3/4 | 4 1/4 | 4.25 | 4.112 | 4.907 | 4.688 | 2 45/64 | 2.759 | 2.647 | 738 |

| 3 | 4 5/8 | 4.625 | 4.475 | 5.34 | 5.102 | 2 61/64 | 3.013 | 2.893 | 950 |

| 3 1/4 | 5 | 5 | 4.838 | 5.774 | 5.514 | 3 3/16 | 3.252 | 3.124 | 1,194 |

| 3 1/2 | 5 3/8 | 5.375 | 5.2 | 6.207 | 5.928 | 3 7/16 | 3.506 | 3.37 | 1,526 |

| 3 3/4 | 5 3/4 | 5.75 | 5.562 | 6.64 | 6.341 | 3 11/16 | 3.76 | 3.616 | 1,812 |

| 4 | 6 1/8 | 6.125 | 5.925 | 7.073 | 6.755 | 3 15/16 | 4.014 | 3.862 | 2,180 |

| Commonly Applied Coatings (A1.1) | ||

|---|---|---|

| Coating Type | Specification | Grade or Class |

| Hot-dip zinc | F2329 | 0.002 in. (50 μm) |

| Mechanically deposited zinc | B695 | Class 55 |

| Zn/Al Coating | F1136 | Grade 5 |

| Zn/Al Coating | F2833 | Grade 1 |

| Zn/Al Coating | F3019 | Grade 4 |

| Zn/Al Coating | F3393 | – |

| Zinc Electroplate | F1941 | Fe/Zn 5AN & Fe/Zn 5C |

| A563 GR.C & C3 Chemical RequirementsA | ||||

|---|---|---|---|---|

| Heat Analysis | C | C3 | ||

| Composition % | Composition A % | Composition B % | Based On Corrosion IndexC | |

| Carbon | 0.55 max | 0.33 – 0.40 | 0.38 – 0.48 | 0.30 – 0.53 |

| Manganese | – | 0.90 – 1.20 | 0.70 – 0.90 | 0.60 min |

| Phosphorus, max | 0.12 | 0.035 | 0.035 | 0.035 |

| Sulfur, max | 0.15D | 0.040 | 0.040 | 0.040 |

| Silicon | B | 0.15 – 0.35 | 0.30 – 0.50 | B |

| Copper | B | 0.25 – 0.45 | 0.20 – 0.40 | 0.20 – 0.60 |

| Nickel | B | 0.25 – 0.45 | 0.50 – 0.80 | 0.20F |

| Chromium | B | 0.45 – 0.65 | 0.50 – 0.75 | 0.45 min |

| Vanadium | B | B | B | B |

| Molybdenum | B | B | 0.06 max | 0.10F min |

| Titanium | B | B | B | B |

| Mechanical Requirements for Gr.C & C3 | ||||||||

|---|---|---|---|---|---|---|---|---|

| Grade of Nut | Nom. Nut Size in. | Style of Nut | Proof Load Stress, ksiA | Hardness | ||||

| Non-Zinc-Coated NutsB | Zinc-Coated NutsB | Brinell | Rockwell | |||||

| min | max | min | max | |||||

| CC | 1/4 to 4 | Heavy Hex | 144 | 144 | 143 | 352 | B78 | C38 |

| C3 | 1/4 to 4 | Heavy Hex | 144 | 144 | 143 | 352 | B78 | C38 |

ASTM A194 Grade 2H nuts, crucial in high-strength applications, are crafted from robust carbon alloy steel, heat-treated for durability in extreme conditions. Available in plain steel or hot-dip galvanized coatings as per ASTM F2329, these nuts ensure adaptability. Widely employed in demanding industries like shipbuilding and oil and gas, their compliance with ASTM A194 Grade 2H standard, guarantee consistent quality. Ideal for secure fastening in challenging environments, they stand as a reliable choice for durable projects.

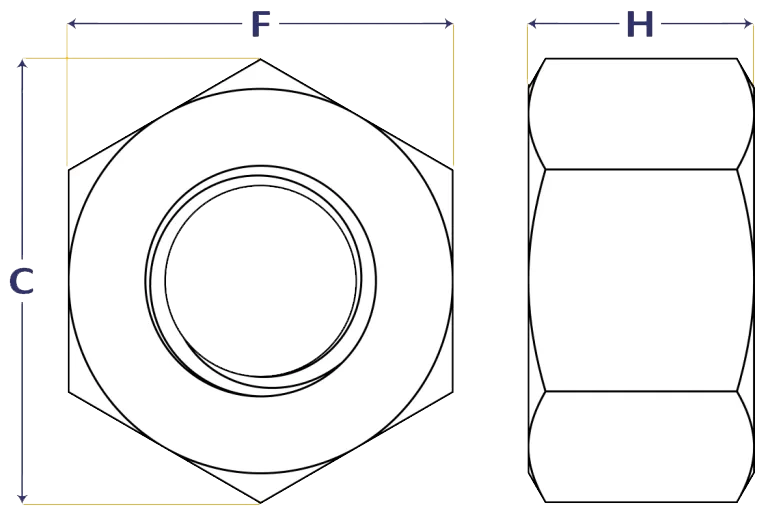

| Nominal Size | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Width Across Flats | Width Across Corners | Thickness | |||||||

| Basic | Max | Min | Max | Min | Basic | Max | Min | ||

| 1/4 | 1/2 | 0.5 | 0.488 | 0.577 | 0.556 | 15/64 | 0.25 | 0.218 | 1 |

| 5//16 | 9/16 | 0.562 | 0.546 | 0.65 | 0.622 | 16/64 | 0.341 | 0.28 | 2 |

| 3/8 | 11/16 | 0.688 | 0.669 | 0.794 | 0.763 | 23/64 | 0.377 | 0.341 | 3 |

| 1/2 | 7/8 | 0.875 | 0.85 | 1.01 | 0.969 | 31/64 | 0.504 | 0.464 | 7 |

| 5/8 | 1 1/16 | 1.062 | 1.031 | 1.227 | 1.175 | 39/64 | 0.631 | 0.587 | 12 |

| 3/4 | 1 1/4 | 1.25 | 1.212 | 1.443 | 1.382 | 47/64 | 0.758 | 0.71 | 20 |

| 7/8 | 1 7/16 | 1.438 | 1.394 | 1.66 | 1.589 | 54/64 | 0.885 | 0.833 | 30 |

| 1 | 1 5/8 | 1.625 | 1.575 | 1.876 | 1.796 | 63/64 | 1.012 | 0.956 | 43 |

| 1 1/8 | 1 13/16 | 1.812 | 1.756 | 2.093 | 2.002 | 1 7/64 | 1.139 | 1.079 | 59 |

| 1 1/4 | 2 | 2 | 1.938 | 2.309 | 2.209 | 1 7/32 | 1.251 | 1.187 | 79 |

| 1 3/8 | 2 3/16 | 2.188 | 2.119 | 2.526 | 2.416 | 1 11/32 | 1.378 | 1.31 | 102 |

| 1 1/2 | 2 3/8 | 2.375 | 2.3 | 2.742 | 2.622 | 1 15/32 | 1.505 | 1.433 | 131 |

| 1 5/8 | 2 9/16 | 2.562 | 2.481 | 2.959 | 2.828 | 1 19/32 | 1.632 | 1.556 | 162 |

| 1 3/4 | 2 3/4 | 2.75 | 2.662 | 3.175 | 3.035 | 1 23/32 | 1.759 | 1.679 | 204 |

| 1 7/8 | 2 15/16 | 2.938 | 2.844 | 3.392 | 3.242 | 1 27/32 | 1.886 | 1.802 | 241 |

| 2 | 3 1/8 | 3.125 | 3.025 | 3.608 | 3.449 | 1 31/32 | 2.013 | 1.925 | 299 |

| 2 1/4 | 3 1/2 | 3.5 | 3.388 | 4.041 | 3.862 | 2 13/64 | 2.251 | 2.155 | 419 |

| 2 1/2 | 3 7/8 | 3.875 | 3.75 | 4.474 | 4.275 | 2 29/64 | 2.505 | 2.401 | 564 |

| 2 3/4 | 4 1/4 | 4.25 | 4.112 | 4.907 | 4.688 | 2 45/64 | 2.759 | 2.647 | 738 |

| 3 | 4 5/8 | 4.625 | 4.475 | 5.34 | 5.102 | 2 61/64 | 3.013 | 2.893 | 950 |

| 3 1/4 | 5 | 5 | 4.838 | 5.774 | 5.514 | 3 3/16 | 3.252 | 3.124 | 1,194 |

| 3 1/2 | 5 3/8 | 5.375 | 5.2 | 6.207 | 5.928 | 3 7/16 | 3.506 | 3.37 | 1,526 |

| 3 3/4 | 5 3/4 | 5.75 | 5.562 | 6.64 | 6.341 | 3 11/16 | 3.76 | 3.616 | 1,812 |

| 4 | 6 1/8 | 6.125 | 5.925 | 7.073 | 6.755 | 3 15/16 | 4.014 | 3.862 | 2,180 |

| Coatings | |

|---|---|

| Coating Type | Specification |

| Electrodeposited Zinc Coatings | B633 |

| Mechanically deposited zinc | B695 |

| Mechanically deposited zinc | B696 |

| Electrodeposited Cadmium Coatings | B766 |

| Zinc Electroplating | F1941 |

| Hot-dip zinc | F2329 |

*Please take note that Boulons Plus only stock Plain and HDG coatings. Other coatings may be available upon request

| A194 Gr.2H Chemical RequirementsA | |

|---|---|

| Heat Analysis | Composition % |

| Carbon | 0.40 min |

| Manganese | 1.00 |

| Phosphorus | 0.040 |

| SulfurE | 0.050 |

| Silicon | 0.40 |

| Chromium | – |

| Nickel | – |

| Molybdenum | – |

| Titanium | – |

| NiobiumH | – |

| Nitrogen | – |

| Copper | – |

| Selenium | – |

| Vanadium | – |

| Aluminium | – |

| Hardness RequirementsA | |||||

|---|---|---|---|---|---|

| Grade & Types | Completed Nuts | Sample Nuts After Treatment as in 8.1.5 | |||

| Brinell Hardness | Rockwell Hardness | Brinell Hardness, min | Rockwell Hardness B Scale, min | ||

| C Scale | B Scale | ||||

| 2H to 1 1/2 in. | 248 to 327 | 24 to 35 | — | 179 | 89 |

| 2H over 1 1/2 in. | 212 to 327 | 35 max | 95 min | 147 | 79 |